- Home

- Lubrication

Systems - Lubricants

& Fluids - Lubrication

Equipment - Contamination

Control - Condition

Monitoring - Services &

Training

![]()

Lubrication Technologies

Your Professional Lubrication Management Team.

Lubrication Technologies, Inc.

120 BOSWORTH ST.

WEST SPRINGFIELD • MA 01089

August 25, 2016

ReliaMAX AUTOMATIC LUBRICATION SYSTEMS

ILC AUTOMATIC LUBRICATION SYSTEMS

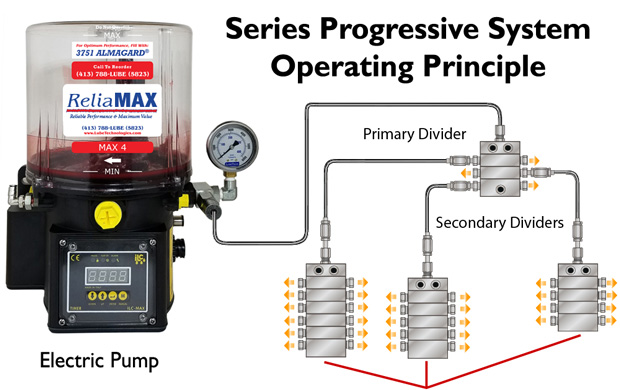

Series Progressive Lubrication Systems

The correct amount of lubricant at the correct time

The correct amount of lubricant at the correct time

Lubrication Technologies, Inc. partners with the most respected brands in the industry to ensure that our customers have access to the lubrication dispensing system that best fits the requirements of each application. We offer automatic lubrication systems, also referred to as automatic grease lubrication systems or auto lube systems, for wheel loaders, auto lube systems for heavy equipment, auto lube systems for trucks, and components for all manufacturing, transportation, maintenance, and industrial applications. Complete systems and individual components available.

We have designed and installed systems for power plants, paper mills, CNC machines, packaging facilities, food processing equipment, heavy equipment, trucks, and many other applications, both large and small.

The series progressive lubrication systems (automatic lubrication systems, centralized lubrication systems) meter oil or grease (up to NLGI 2) via distribution blocks (divider valves) to lubricate the friction points of the machines. Each divider valve can serve between 3 and 24 outlets with accurate discharge to each point. The distribution system is reliable and can be monitored by an electrical switch on the primary divider, as well as visual observation of an indicator pin.

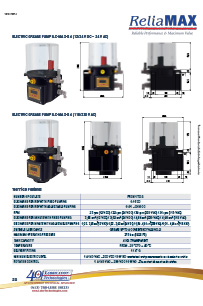

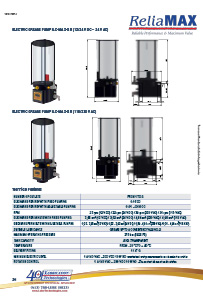

Pumps are available in 12/24 VDC, 115/230VAC, or pneumatic or hydraulically powered. We offer Integrated controllers, separate controllers as well as customized controls utilizing PLC’s, HMI’s, zoned operation and real time monitoring.

Lubrication Technologies, Inc. is the exclusive North American Distributor for ILC.

ILC is renowned worldwide for its centralized grease and oil automatic lubrication systems. Its modern factory is located in at Gorla Minore (Va) – Italy.