- Home

- Lubrication

Systems - Lubricants

& Fluids - Lubrication

Equipment - Contamination

Control - Condition

Monitoring - Services &

Training

![]()

Lubrication Technologies

Your Professional Lubrication Management Team.

Lubrication Technologies, Inc.

120 BOSWORTH ST.

WEST SPRINGFIELD • MA 01089

August 25, 2016

LE GEAR LUBRICANTS

The number one cause of failure in any mechanical application is contamination

Every industrial plant has a sizeable investment in both its equipment and the lubricant that is purchased to protect that equipment, so it only makes sense to protect these assets. A good lubrication reliability program in place to prevent contamination will protect the equipment and the lubricant, which in turn will eliminate or greatly reduce unscheduled downtime as well as increase profits.

Every industrial plant has a sizeable investment in both its equipment and the lubricant that is purchased to protect that equipment, so it only makes sense to protect these assets. A good lubrication reliability program in place to prevent contamination will protect the equipment and the lubricant, which in turn will eliminate or greatly reduce unscheduled downtime as well as increase profits.

Industrial gearboxes are expected to perform under conditions of high heat and heavy loads; and in environments often contaminated with dirt, process debris and water. Without adequate protection, gears will wear prematurely. You’ll have to replace parts more frequently, change oil more frequently, and worst of all, you’ll experience equipment downtime. To combat difficult conditions, LE offers an array of lubricants specially formulated for enclosed industrial gearbox applications.

Some of the common suffering points for gearbox applications are oil foaming, overheating, and emulsification – all caused or aggravated by use of the wrong oil for the application; and contaminant ingression that leads to lubricant failure and mechanical wear. All of these suffering points can be solved by implementing the following six lubrication reliability best practices for gearboxes.

- Install desiccant breather

- Install sight glass

- Select and use the right high-performance gear oil for the application

- Implement oil analysis

- Filter to 17/16/13 cleanliness code

- Implement color-coding & tagging

Best Practices for Gearboxes

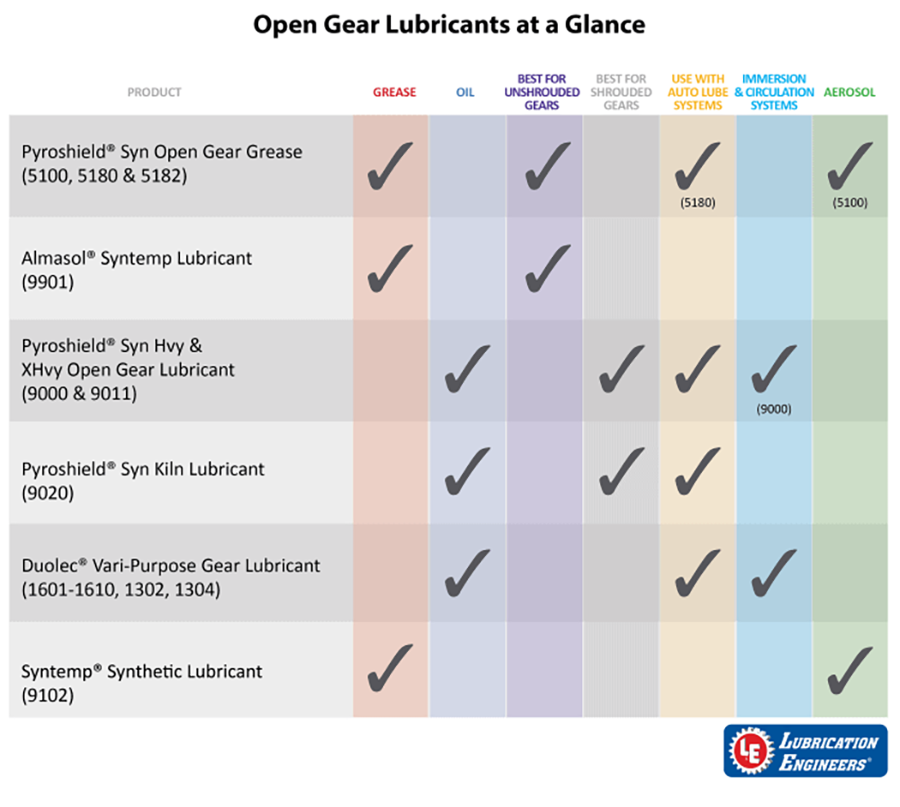

Open Gear Lubricants

Self-Healing Fluid Seals & Protects Surfaces

Open Gear Lubricants

Open Gear Lubricants

Large open gears on grinding and pulverizing mills present significant lubrication challenges due to the high-load, heavy-shock nature of the application and constant exposure to harsh environmental conditions, such as cement, limestone, coal or silica dust. Lubrication reliability best practices for open gears include selecting the right lubricant and the right method of application to combat these challenges. Choosing wisely will help protect the gears from wear, increase uptime, and – in most cases – dramatically reduce gear set operating temperatures, lubricant consumption, energy consumption, and waste disposal. This will lead to a cleaner, safer working environment. The right choice for open gears is a heavy-duty, high viscosity lubricant with an extreme pressure, anti-wear additive package. A lubricant with a Timken rating of 70 pounds or more reduces wear and extends gear life.

In the past, open gear lubricants were asphaltic-based, had Timken ratings of 20 to 25 pounds, and relied on excessive volume for adequate protection. Most open gear lubricants on the market today use a variety of thickeners, such as graphites, silicas and traditional soap thickeners. With these newer types of lubricants, operators still report excessive consumption that leads to difficulty with the lubricants building up around the shrouds, not draining well and creating housekeeping issues.

Other concerns include needing to be heated for pumpability, plugging spray system nozzles, not spraying in low temperatures, drawing in contaminants, obscuring the gear from visual inspection, and not reducing gear temperatures.

Lubrication Engineers Pyroshield®. line of heavy-duty synthetic open gear lubricants can help protect your valuable equipment and keep it running harder and lasting longer. If you are interested in making your large open gears last longer, lowering the amount of lubricant you use, and reducing overall maintenance expenditures, then we have the solutions for you. Call our consultants at Lubrication Technologies (413) 788-5823. for more information on LE Products.

LE Pyroshield Lubricants

Pyroshield® Syn Open Gear Grease (5182, 5180 & 5100) is a heavy-duty synthetic lubricant developed for large unshrouded open gears in the mining, mineral processing and cement industries, and for other severe service applications that require a lubricant with superior wear protection, exceptional load-carrying ability, ou8tstanding tackiness and ease of application at various temperatures. It also works well for applications in which gears experience high point-of-contact temperatures of 327°C (620°F) and above.

Almasol Syntemp Lubricant (9901) is excellent for use on large open gears exposed to very high temperatures. It is also recommended for use on kiln girth gears, large industrial gearing, oven chains, sliding surfaces, large slow moving (friction) bearings and similar applications.

Pyroshield® Syn Hvy & XHvy Open Gear Lubricants (9000 & 9011) are heavyduty synthetic fluids designed to provide outstanding protection for high-load, heavy-shock applications, such as large shrouded open gears used in the mining, mineral processing and cement industries. Pyroshield Syn Open Gear Lubricants are non-asphaltic and environmentally friendly, containing no heavy metals. Each lubricant features a synergistic mix of Almasol®, LE’s exclusive wear-reducing additive, and a unique combination of extreme pressure additives.

Pyroshield® Syn Kiln Lubricant (9020) is a heavy-duty synthetic fluid designed to provide exceptional protection for high-load, heavy-shock, high-heat applications, particularly large shrouded and unshrouded open gears servicing kilns and ball mills in the mining, mineral processing and cement industries. It is recommended for slow-moving, straight-cut gear sets where flaking occurs using a conventional open gear lubricant. Pyroshield Syn Kiln Lubricant is formulated with a synergistic mix of extreme pressure and wear-reducing additives, including solid particles of fine graphite and of Almasol®, LE’s exclusive wear-reducing solid additive. It is non-asphaltic and environmentally friendly, containing no heavy metals.

Syntemp® Synthetic Lubricant (9102) is a heavy-duty spray grease designed for open gears, chains, cables, sealed bearings and slides - or any hard-to-reach area. Available in an aerosol can, it is excellent for high-temperature applications and will not melt. It is extremely tacky and water-resistent, staying in place without slinging or dripping. Syntemp Synthetic Lubricant includes extreme pressure characteristics to protect against heavy loads while preventing rust and corrosion. This mechanically stable grease has an exceptionally high film strength that resists rupturing and protects against metal-to-metal contact. It contains Monolec, LE's exclusive wear-reducing additive.

To learn more about each of lubricants, click on the photos below

9901 Almasol Syntemp Lubricant High temperature lubricant made from a very heavy synthetic fluid and a nonmelting base. It is specially formulated to provide exceptional protection at temperatures at which petroleum oils would completely oxidize or carbonize. Contains Almasol, LE's exclusive wear-reducing additive.

9102 Syntemp® Synthetic Lubricant is unique, heavy duty, high temperature spray lubricant designed for open gears, chains, cables, sealed bearings and slides - or any "tight" area where grease lubrication can be best accomplished by the spray method. Its superior lubricating qualities reduce wear, friction and heat far more effectively than ordinary greases.

5100 Pyroshield Synthetic Open Gear Grease is a heavy-duty synthetic lubricant developed for large unshrouded open gears in the mining, mineral processing and cement industries, and for other severe service applications that require a lubricant with superior wear protection, exceptional load-carrying ability, outstanding tackiness and ease of application at various temperatures. It also works well for applications in which gears experience high point-of-contact temperatures of 327°C (620°F) and above.

5180-5182 Pyroshield Synthetic Open Gear Grease is a heavy-duty synthetic lubricant developed for large unshrouded open gears in the mining, mineral processing and cement industries, and for other severe service applications that require a lubricant with superior wear protection, exceptional load-carrying ability, outstanding tackiness and ease of application at various temperatures. It also works well for applications in which gears experience high point-of-contact temperatures of 327°C (620°F) and above.

9000 & 9011 Pyroshield® Heavy-duty synthetic fluids designed to provide outstanding protection for high-load, heavy-shock applications, such as large shrouded open gears used in the mining, mineral processing and cement industries. Each lubricant features a synergistic mix of Almasol®, LE's exclusive wear-reducing additive, and a unique combination of extreme pressure additives.

9020 Pyroshield® Syn Kiln Lubricant Heavy-duty synthetic fluid designed to provide exceptional protection for high-load, heavy-shock, high-heat applications, particularly large shrouded and unshrouded open gears servicing kilns and ball mills in the mining, mineral processing and cement industries. It is recommended for slow-moving, straight-cut gear sets where flaking occurs using a conventional open gear lubricant.

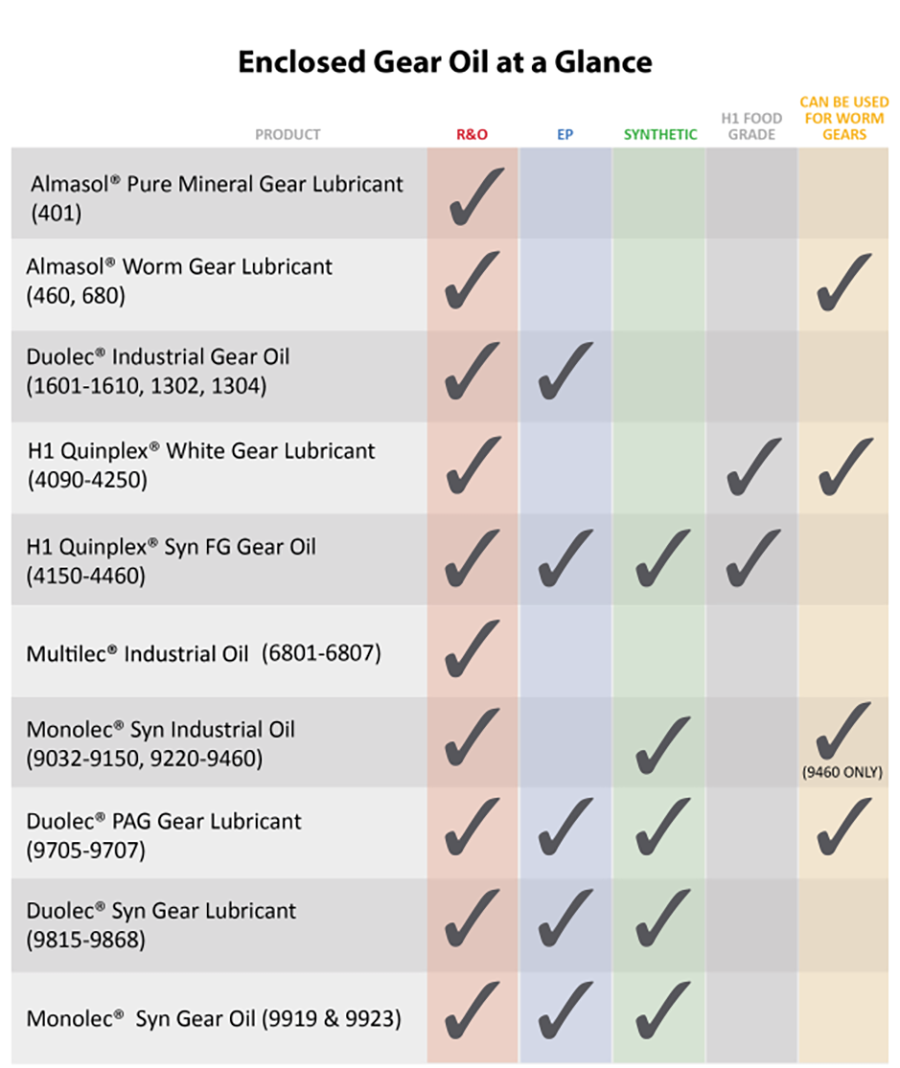

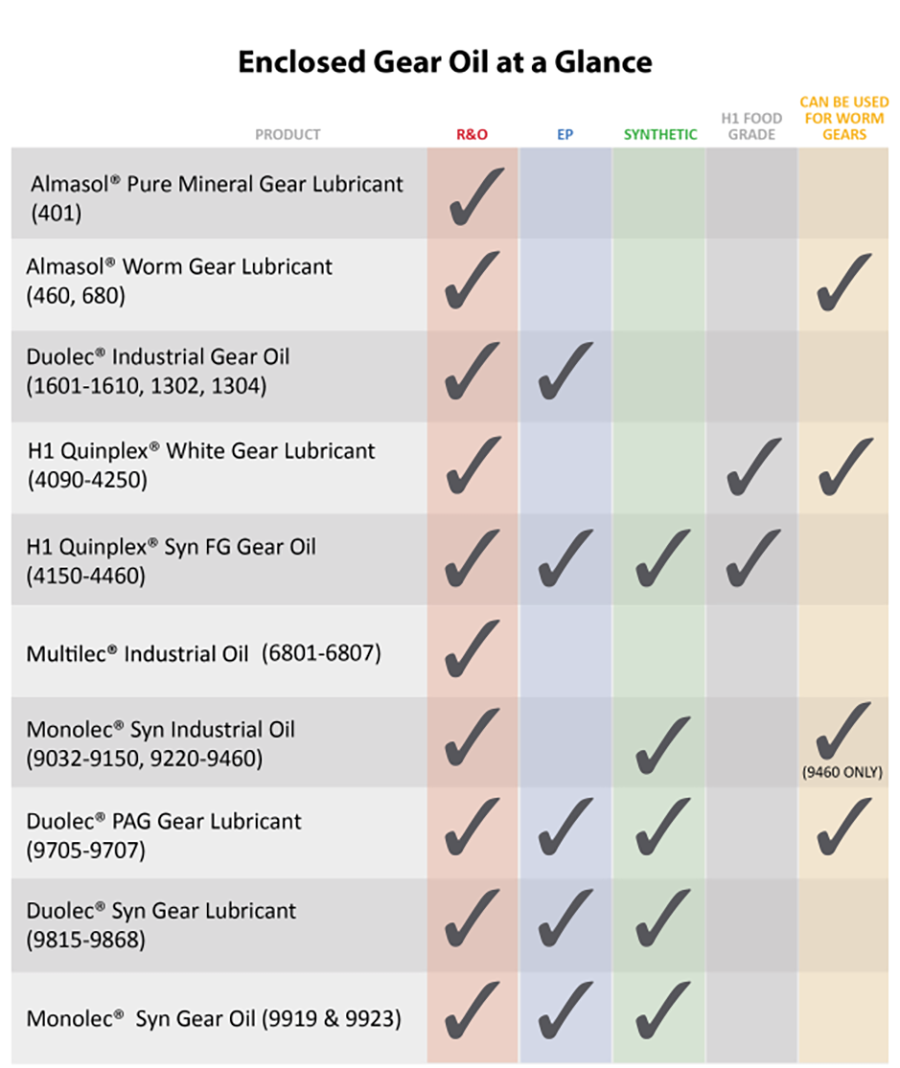

ENCLOSED GEAR LUBRICANTS - INDUSTRIAL

LE’s industrial oils work for countless applications

Encolosed Gears

Encolosed Gears

Gear oil is made up of two critical components: base oil and additives. Additives impart desirable properties and suppress undesirable ones. The additive package is the backbone of the lubricant’s performance, and a strong backbone will provide the performance and protection you need. When selecting gear oil, there are three essential attributes to consider:

One – The gear oil must remain thermally stable and not oxidize at high temperatures, thus avoiding the creation of sludge or varnish. Keeping the oil from oxidizing will lengthen drain and replacement intervals. As a general rule of thumb, for every 18 degrees F (10 degrees C) increase in fluid temperature above 140°F (60°C), oxidation will reduce the service life of a lubricant by half.

Two – If you have an enclosed gearbox application that is heavily loaded or subject to shock loading, you need gear oil with extreme pressure properties. Gear oil with an EP additive will protect the gear surfaces against extreme pressures.

Three – Gear oil must fight contamination that enters the system, especially water. The oil must be able to demulsify, which allows for easy removal of the water from the gearbox.

Almasol® Pure Mineral Gear Lubricant (401) is a balanced formulation of high VI base oils, rust and oxidation inhibitors, and other additives – including Almasol®, LE’s exclusive wear-reducing additive – that provide the highest level of wear reduction possible without the use of a chemically active EP agent.

Almasol® Worm Gear Lubricant (460, 680) is blended with stable lubricity additives and LE’s proprietary additive Almasol® to reduce friction and provide protection in a wide temperature range. It protects bronze bull gears from excessive wear in enclosed worm gearboxes, providing superior oxidation resistance in high-temperature applications where extreme pressure (EP) gear lubricants cannot be used.

Other LE gear oils that may work for specific worm gear applications include:

Duolec® PAG Gear Lubricant (9705-9707) is a PAG gear oil that has been specially formulated for the ultimate in corrosion resistance, wear protection and thermal stability. Polyalkylene glycol (PAG) lubricants are synthetic formulations known for their high viscosity index, extreme pressure (EP) properties, and ability to handle temperature extremes. Duolec PAG Gear Lubricant is an excellent choice for lubricating a variety of bearings and gears – particularly worm gears – as well as other equipment operating under extreme conditions.

Duolec® Syn Gear Lubricant (9815-9868) works to prevent deposit formations in high-temperature applications and will not break down over time. The lubricant also provides exceptional low-temperature flow properties, protecting gears during the coldest startups.

H1 Quinplex® White Gear Lubricant (4090-4250) is NSF H1 registered for incidental food contact. This extremely pure, nonstaining, odorless, tasteless, non-irritating lubricant can be used with confidence where incidental food contact or staining can occur. H1 Quinplex White Gear Lubricant was designed for use in heavily loaded food processing gear applications – including worm gears – that call for an anti-wear, R & O lubricant capable of preventing corrosion. It contains a blend of mineral and synthetic base stocks to provide superior protection at a variety of operating temperatures. For good metal adhesion, it also contains tackifiers, including Quinplex®, LE’s proprietary impact-resistant additive that contributes to outstanding water resistance, tackiness and enhanced mechanical stability.

H1 Quinplex® Syn FG Gear Oil (4150-4460) is NSF H1 registered for incidental food contact and was formulated to withstand severe loading conditions and prevent rust and corrosion. H1 Quinplex Syn FG Gear Oil contains 100 percent synthetic base stock to provide superior protection in extreme high and low temperatures. It also offers great seal compatibility and excellent nonfoaming qualities. Its anti-wear capability differentiates it from many other white oils on the market. To ensure good metal adhesion, it contains a shear stable polymeric tackifier system including Quinplex®, LE’s proprietary impact-resistant additive. H1 Quinplex Syn FG Gear Oil helps factories avoid unplanned downtime and expensive repairs by providing longlasting, reliable protection that keeps critical equipment running in extreme temperatures.

Multilec® Industrial Oil (6801-6807) Multilec® Industrial Oil is a heavy-duty oil designed to prolong equipment life by combating the effects of high temperatures, water, contaminants and heavy loads that accelerate wear. Available in seven different viscosity grades, this multipurpose lubricant is ideally suited for use in all types of air compressors, hydraulics, oil circulating systems, industrial turbines, and R & O industrial and gear applications.

Monolec® Syn Industrial Oil (9919 & 9923) Monolec® Syn Gear Oil (9919 & 9923) is a 100 percent synthetic, limited slip gear oil with a high-performance additive package, making it an ideal choice for transmissions and differentials that encounter severe service conditions, including fleets of delivery trucks, heavy-duty pickup trucks, school buses, and bucket trucks. Its high-performance formula will not break down in severe service. It resists gear and bearing wear, viscosity loss, foaming, high-temperature oxidation, and volatility, allowing it to deliver long-lasting protection for any application where extreme pressure and shock loading is expected, including industrial gearboxes that require enhanced EP protection.

To learn more about each of lubricants, click on the photos below

Gear Oils (EP/Antiscuff)

Duolec Industrial Gear Oil 1601-1610, 1302-1304 is a high-performance industrial gear oil with ISO grades ranging from ISO VG 46 to 1500. Designed for use in any industrial gear or bearing application that requires a thermally stable, extreme pressure/antiscuff lubricant, it maintains performance even after filtration.

Duolec® PAG Gear Lubricant 9705 - 9707 specially formulated for the ultimate in corrosion resistance, wear protection and thermal stability. Duolec PAG Gear Lubricant is an excellent choice for lubricating a variety of bearings and gears – particularly worm gears – as well as other equipment operating under extreme conditions.

Duolec Synthetic Gear Lubricant 9815-9868 provides uninterrupted operation and long service life for expensive gear applications, including heavily loaded gearboxes that are exposed to temperature extremes. With its special blend of clean gear technology additives, Duolec Syn Gear Lubricant works to prevent deposit formations in high-temperature applications and will not break down over time. The lubricant also provides exceptional low temperature flow properties, protecting gears during the coldest startups.

Monolec® Syn Gear Oil (9919 & 9923) is an ideal choice for transmissions and differentials that encounter severe service conditions, including fleets of delivery trucks, heavy-duty pickup trucks, school buses, and bucket trucks. Its high-performance formula will not break down in severe service. It resists gear and bearing wear, viscosity loss, foaming, high-temperature oxidation, and volatility, allowing it to deliver long-lasting protection for any application where extreme pressure and shock loading is expected, including industrial gearboxes that require enhanced EP protection.

H1 QUINPLEX SYN FG GEAR OIL 4150, 4220, 4320, 4460 recommended for a variety of gearboxes and other critical applications in food and beverage manufacturing facilities,H1 Quinplex® White Gear Lubricant (4090-4250) is NSF H1 registered for incidental food contact and was formulated to withstand severe loading conditions and prevent rust and corrosion. H1 Quinplex White Gear Lubricant contains a carefully selected blend of pure mineral and synthetic base stocks to provide superior protection at a wide range of operating temperatures.

Gear Oils (R&O)

Almasol® Pure Mineral Gear Lubricant 401 is a balanced formulation of base oil, rust and oxidation inhibitors, wear-reducing agents, and other additives that provides the highest level of protection possible without the inclusion of an extreme pressure additive. Almasol® solid wear-reducing additive is able to withstand extremely heavy loads, chemical attack and temperatures up to 1,900°F (1,038°C). It is attracted to metal surfaces, forming a microscopic layer but not building on itself or affecting clearances. Almasol minimizes metal-to-metal contact and the resulting friction, heat and wear.

H1 Quinplex® White Gear Lubricant 4090, 4140, 4250 recommended for a variety of gearboxes and other critical applications in food and beverage manufacturing facilities,H1 Quinplex® White Gear Lubricant (4090-4250) is NSF H1 registered for incidental food contact and was formulated to withstand severe loading conditions and prevent rust and corrosion. H1 Quinplex White Gear Lubricant contains a carefully selected blend of pure mineral and synthetic base stocks to provide superior protection at a wide range of operating temperatures.

Monolec® Syn Industrial Oil 9032 - 9150 & 9220 - 9460 Monolec Syn Industrial Oil (9032-9150, 9220-9460) is designed to prolong equipment life by combating the effects of high temperatures, contamination and loads that accelerate wear.

Multilec Industrial Oil 6801-6807 LE’s Multilec® Industrial Oil is a heavy-duty oil designed to prolong equipment life by combating the effects of high temperatures, water, contaminants and heavy loads that accelerate wear.

Worm Gear Oils

LE ALMASOL WORM GEAR LUBRICANT 460-680 LE's Gear Lubricants are formulated with 100% mid-continent Paraffinic base oils blended with stable lubricity additives and ALMASOL® to provide protection in a wide temperature range..

Duolec® PAG Gear Lubricant 9705 - 9707 LE’s Duolec® PAG Gear Lubricant (9705-9707) is a PAG gear oil that has been specially formulated for the ultimate in corrosion resistance, wear protection and thermal stability.

H1 Quinplex® White Gear Lubricant 4090, 4140, 4250 recommended for a variety of gearboxes and other critical applications in food and beverage manufacturing facilities. H1 Quinplex® White Gear Lubricant (4090-4250) is NSF H1 registered for incidental food contact and was formulated to withstand severe loading conditions and prevent rust and corrosion. H1 Quinplex White Gear Lubricant contains a carefully selected blend of pure mineral and synthetic base stocks to provide superior protection at a wide range of operating temperatures.

Monolec® Syn Industrial Oil 9460 designed to prolong equipment life by combating the effects of high temperatures, contamination and loads that accelerate wear. It is a versatile synthetic lubricant that meets or exceeds the requirements of gearboxes, air compressors, vacuum pumps, hydraulic systems, and roll mill bearings found in the textile, plastic, rubber and paper industries.

ENCLOSED GEAR LUBRICANTS - FOOD GRADE

LE’s industrial oils work for countless applications

When it comes to food, beverage and pharmaceutical applications, Lubrication Engineers food grade oil and food grade grease can play a significant role in preventing costly damage brought on by severe operating conditions. Our high-performance food grade greases and oils are registered NSF H1 for incidental food contact, certified Kosher Pareve, and certified Halal by IFANCA – making them suitable for use in food manufacturing plants.

When it comes to food, beverage and pharmaceutical applications, Lubrication Engineers food grade oil and food grade grease can play a significant role in preventing costly damage brought on by severe operating conditions. Our high-performance food grade greases and oils are registered NSF H1 for incidental food contact, certified Kosher Pareve, and certified Halal by IFANCA – making them suitable for use in food manufacturing plants.

Regardless of load, temperature, environment and speed, LE has a suitable food machinery lubricant solution for your facility. Some of LE’s food machinery lubricants are additive-free USP-grade white mineral oils, while others contain our exclusive additive Quinplex that imparts various qualities to our food machinery lubricants, including impact resistance, wear reduction, and increased oil film strength.

Our formulation of food grade greases and oils have been used in food manufacturing operations for years to provide dependable reliable operation. Typical applications where our customers have used LE’s food grade lubricants include blenders, bottle washers, cams, conveyors, gearboxes, slides, conveyer chains, cookers, bottling machines, packaging equipment, valves, hydraulics, canning machines, bushings and more. We have hundreds of testimonials showcasing how we have helped customers with their lubrication reliability, including critical applications and equipment.

< Click Graphic to Enlarge

H1 Quinplex® White Gear Lubricant (4090, 4140, 4250) Recommended for a variety of gearboxes and other critical applications in food and beverage manufacturing facilities, H1 Quinplex® White Gear Lubricant (4090-4250) is NSF H1 registered for incidental food contact and was formulated to withstand severe loading conditions and prevent rust and corrosion. H1 Quinplex White Gear Lubricant contains a carefully selected blend of pure mineral and synthetic base stocks to provide superior protection at a wide range of operating temperatures. It also offers antiwear protection, differentiating it from many other white oils on the market. To ensure good metal adhesion, it contains a shear stable polymeric tackifier system including Quinplex®, LE’s proprietary impact-resistant additive.

H1 Quinplex® Syn FG Gear Oil (4150-4460) Recommended for a variety of gearboxes and other critical applications in food and beverage manufacturing facilities, H1 Quinplex® Syn FG Gear Oil (4150-4460) is NSF H1 registered for incidental food contact and was formulated to withstand severe loading conditions and prevent rust and corrosion. H1 Quinplex Syn FG Gear Oil contains 100 percent synthetic base stock to provide superior protection in extreme high and low temperatures. It also offers great seal compatibility and excellent nonfoaming qualities. Its anti-wear capability differentiates it from many other white oils on the market. To ensure good metal adhesion, it contains a shear stable polymeric tackifier system including Quinplex®, LE’s proprietary impact-resistant additive. H1 Quinplex Syn FG Gear Oil helps factories avoid unplanned downtime and expensive repairs by providing longlasting, reliable protection that keeps critical equipment running in extreme temperatures.

To learn more about each of lubricants, click on the photos below

H1 Quinplex White Gear Lubricant (Food Grade)

H1 Quinplex® White Gear Lubricant 4090, 4140, 4250 recommended for a variety of gearboxes and other critical applications in food and beverage manufacturing facilities. H1 Quinplex® White Gear Lubricant (4090-4250) is NSF H1 registered for incidental food contact and was formulated to withstand severe loading conditions and prevent rust and corrosion. H1 Quinplex White Gear Lubricant contains a carefully selected blend of pure mineral and synthetic base stocks to provide superior protection at a wide range of operating temperatures.

H1 QUINPLEX SYN FG GEAR OIL 4150, 4220, 4320, 4460 recommended for a variety of gearboxes and other critical applications in food and beverage manufacturing facilities,H1 Quinplex® White Gear Lubricant (4090-4250) is NSF H1 registered for incidental food contact and was formulated to withstand severe loading conditions and prevent rust and corrosion. H1 Quinplex White Gear Lubricant contains a carefully selected blend of pure mineral and synthetic base stocks to provide superior protection at a wide range of operating temperatures.

Food Grade Certifications

ENCLOSED GEAR LUBRICANTS - MOBILE APPLICATIONS

LE’s industrial oils work for countless applications

Almasol® Pure Mineral Gear Lubricant (401) is a balanced formulation of high VI base oils, rust and oxidation inhibitors, and other additives – including Almasol®, LE’s exclusive wear-reducing additive – that provide the highest level of wear reduction possible without the use of a chemically active EP agent.

Almasol® Pure Mineral Gear Lubricant (401) is a balanced formulation of high VI base oils, rust and oxidation inhibitors, and other additives – including Almasol®, LE’s exclusive wear-reducing additive – that provide the highest level of wear reduction possible without the use of a chemically active EP agent.

Monolec® Gear Lubricant (703-704) offers the versatility of one product that meets the demanding fleet requirements of all types of differentials (including limited slip) and transmissions, as well as most industrial enclosed gearboxes. A multiviscosity extreme pressure gear oil, Monolec Gear Lubricant was formulated to achieve the proper balance between load-carrying capacity, film strength and lubricity.

Monolec® Syn All-Climate Gear Lubricant (9919-9923)

is a versatile synthetic lubricant that meets or exceeds the requirements of gearboxes, air compressors, vacuum pumps, hydraulic systems, and roll mill bearings found in the textile, plastic, rubber and paper industries. It is formulated with high-viscosity 100 percent synthetic base oil and a specially developed additive package for applications running at extreme temperatures. The additive package provides outstanding thermal stability and rust and oxidation resistance as well as wear resistance as pressures and temperatures rise. A foam suppressant completes the package. The base oil and additive formulation works synergistically to reduce wear, extend oil drain intervals, reduce oil consumption, and practically eliminate deposits and sludge formation, all while providing excellent compatibility with seals.

To learn more about each of lubricants, click on the photos below

Almasol® Pure Mineral Gear Lubricant 401 is a balanced formulation of base oil, rust and oxidation inhibitors, wear-reducing agents, and other additives that provides the highest level of protection possible without the inclusion of an extreme pressure additive. Almasol® solid wear-reducing additive is able to withstand extremely heavy loads, chemical attack and temperatures up to 1,900°F (1,038°C). It is attracted to metal surfaces, forming a microscopic layer but not building on itself or affecting clearances. Almasol minimizes metal-to-metal contact and the resulting friction, heat and wear.

Monolec® Gear Lubricant 703-704 offers the versatility of one product that meets the demanding fleet requirements of all types of differentials (including limited slip) and transmissions, as well as most industrial enclosed gearboxes. A multiviscosity extreme pressure gear oil, Monolec Gear Lubricant was formulated to achieve the proper balance between load-carrying capacity, film strength and lubricity.

Monolec® Syn Gear Oil (9919 & 9923) is a 100 percent synthetic, limited slip gear oil with a high-performance additive package, making it an ideal choice for transmissions and differentials that encounter severe service conditions, including fleets of delivery trucks, heavy-duty pickup trucks, school buses, and bucket trucks. Its high-performance formula will not break down in severe service. It resists gear and bearing wear, viscosity loss, foaming, high-temperature oxidation, and volatility, allowing it to deliver long-lasting protection for any application where extreme pressure and shock loading is expected, including industrial gearboxes that require enhanced EP protection.