- Home

- Lubrication

Systems - Lubricants

& Fluids - Lubrication

Equipment - Contamination

Control - Condition

Monitoring - Services &

Training

![]()

Lubrication Technologies

Your Professional Lubrication Management Team.

Lubrication Technologies, Inc.

120 BOSWORTH ST.

WEST SPRINGFIELD • MA 01089

August 25, 2016

BULK FLUID AND LUBRICANT STORAGE

Oil Safe® Lubrication Work Center Create an instant lube room with the Oil Safe® Lubrication Work Center, brought to you in partnership with Fluid Defense and Lubrication Engineers. This base system is the ultimate convenience in implementing a lube room that incorporates all the best practice solutions for storage and dispensing of lubricating oils and glycol based coolants. A storage cabinet below the dispensing station ensures that fluid handling tools, equipment and identification parts are organized and easily available and is sized to accomodate hose reels, if you choose to upgrade your dispensing systems. Choose between 10 color-coded tanks in 4 tank sizes (30, 65, 120 & 240 gallon) constructed of TGIC polyester powder coated 12 gauge steel, each with it's own pump, filter and suction tube. Ships assembled and virtually ready to use.

Create an instant lube room with the Oil Safe® Lubrication Work Center, brought to you in partnership with Fluid Defense and Lubrication Engineers. This base system is the ultimate convenience in implementing a lube room that incorporates all the best practice solutions for storage and dispensing of lubricating oils and glycol based coolants. A storage cabinet below the dispensing station ensures that fluid handling tools, equipment and identification parts are organized and easily available and is sized to accomodate hose reels, if you choose to upgrade your dispensing systems. Choose between 10 color-coded tanks in 4 tank sizes (30, 65, 120 & 240 gallon) constructed of TGIC polyester powder coated 12 gauge steel, each with it's own pump, filter and suction tube. Ships assembled and virtually ready to use.

- Durable poly tanks

- Metal stand (36-inch height)

- Drip-tray holders, pans and screens

- Elbow mounts

- Brass spring release valves

- PFSB fittings and FP90 poly fittings

- Des-Case standard desiccant breathers (not shown)

- 200-gal secondary containment vessel (not shown)

- Gravity feed (shown), with pump options available, including 24" H Stand, Drip Tray Assembly and GF Dispense Kit w/valves, plastic tubing, sealant, etc.

The OilSafe lubrication management system establishes best practices throughout your facility. Every step is color-coded to eliminate risk and human error, simplyfing maintenance and extending the life of your equipment. Keep your business running with OilSafe. Contact us (413) 788-5823 to learn more.

OILSAFE® SINGLE STATION LUBE STORAGE & DISPENSING

55 Gallon Drum Work Station

Delivers best practice contamination control for 55 gallon drums in a space efficient form featuring a compact footprint - 14"w x 24'd x 65"h.

- Positive displacement Gear Pump (3-5GPM) with internal bypass

- 2-way filtration (discharge and re-circulate “kidney-loop”)

- Comes standard with 7µ, β2000 Spin on filter (4µ and 25µ also available)

- Desiccant Air Breather for Drum ventilation integrity

- Stainless Steel Dispensing Console with drip pan

- Electronic Stop/Start buttons

- Dedicated Stainless/PVC Suction Spear/Hose for Drum

- Hose Assembly with quick connects

- Delivered pre-assembled and ready-to-use

- Size: 14"(w) x 24"(d) x 65"(h)

- Drum can be placed on any standard Drum Deck/Spill Pallet for SPCC Spill Compliance if required

Note: 55 Gallon Drum and XPELTM Container not included.

Oil Safe® Tote Dispensing Rack with Reel

Best practice contamination control for common 300 gallon totes with base dimensions less than 41"w x 46"d. This space efficient design lifts the tote off the ground for easy dispensing. Additional spill pans available to expand capacity if SPCC compliance is required. Ships assembled and virtually ready to use, just attach the tote and connect the hose (hose adapter may be necessary, available from the tote supplier), plug it in and you have a best practice dispensing rack. Ships complete with:

- Positive displacement gear pump (3 or 5 gpm) with internal bypass

- Retractable hose dispensing reel (25 ft) with trigger dispenser

- 12µm, ß1000 HP filter with DP indicator (3, 7 and 22 µm are also available; email or call for options)

- Electronic stop / start buttons

- Rack will accomodate Totes with base dimensions less than 41" (w) x 46" (d)

- Delivered pre-assembled and ready-to-use

- Additional Spill Pans available to expand Spill Pan capacity if SPCC Compliance is required

Note: Tote not included.

Des-Case Lubricant Storage and Handling - LMS System

LT-LMS Bulk Storage

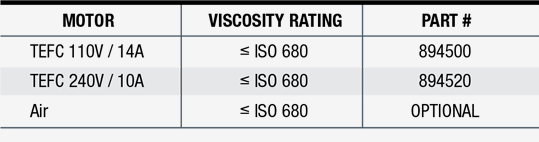

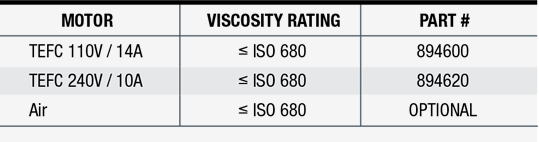

Simple, stackable and easy storage meets solid contamination control practices in a unique design with the Des-Case LT-Series Lubricant Management System (LT-LMS). Dedicated filtration per container ensures no cross-contamination of fluids, while disposable desiccant breathers prevent dirt and water ingression. These all-in-one systems are completely customizable− offering various flow rates, container sizes, quick connect fittings, steel and HDPE tanks, and accessories. And even better yet, these systems are easy to use and install.

Simple, stackable and easy storage meets solid contamination control practices in a unique design with the Des-Case LT-Series Lubricant Management System (LT-LMS). Dedicated filtration per container ensures no cross-contamination of fluids, while disposable desiccant breathers prevent dirt and water ingression. These all-in-one systems are completely customizable− offering various flow rates, container sizes, quick connect fittings, steel and HDPE tanks, and accessories. And even better yet, these systems are easy to use and install.

- Storage Tanks

- Wind Turbines

- Large Gearboxes

- Remote Applications

Applications

- Automatic pressure relief valve

- Dedicated pump and motor per tank

- Desiccant breathers

- Heavy-duty stand

- 12' hose assemblies with various hoseend connections

- One-year warranty

- Industrial powder-coated paint

To meet the specific needs of a wide variety of industrial customers, Lubrication Enginners offers four different lubricant bulk tanks, including returnable and disposable options. These bulk tanks offer several advantages over smaller size containers, including a smaller environmental impact.

To meet the specific needs of a wide variety of industrial customers, Lubrication Enginners offers four different lubricant bulk tanks, including returnable and disposable options. These bulk tanks offer several advantages over smaller size containers, including a smaller environmental impact.