- Home

- Lubrication

Systems - Lubricants

& Fluids - Lubrication

Equipment - Contamination

Control - Condition

Monitoring - Services &

Training

![]()

Lubrication Technologies

Your Professional Lubrication Management Team.

Lubrication Technologies, Inc.

120 BOSWORTH ST.

WEST SPRINGFIELD • MA 01089

August 25, 2016

ADDITIONAL LE PRODUCTS

Not resting on its laurels, LE's state-of-the-art technology center engages in full-time research and development, ensuring our customers that the most effective technology is available for incorporation into the LE product line, whether intended for a conventional application or an extremely specialized niche application, such as those outlined below.

Not resting on its laurels, LE's state-of-the-art technology center engages in full-time research and development, ensuring our customers that the most effective technology is available for incorporation into the LE product line, whether intended for a conventional application or an extremely specialized niche application, such as those outlined below.

Lubricant Bulk Tanks | Dry Film Lubricant | Industrial Products | Oven Chain Lubricants | Penetrating Oils | Wire Rope Lubricants | Industrial Products

Lubrication Engineers' Lubricant Bulk Tanks

LE Lubricant Bulk Tanks

To meet the specific needs of a wide variety of industrial customers, Lubrication Enginners offers four different lubricant bulk tanks, including returnable and disposable options. These bulk tanks offer several advantages over smaller size containers, including a smaller environmental impact.

To meet the specific needs of a wide variety of industrial customers, Lubrication Enginners offers four different lubricant bulk tanks, including returnable and disposable options. These bulk tanks offer several advantages over smaller size containers, including a smaller environmental impact.

Bulk tanks eliminate the problem of drum deposits and the cost and liability associated with the disposal of used drums. As government regulations for dispoal of used drums become stricter, bulk tanks become more attactive alternative. Almost all LE products are available in bulk tanks. Bulk tanks ensure an adequate, fresh supply of LE lubricants at your location at all times. They do not require as much storage space as an equivalent volume of product in smaller containers. They reduce inventory requirements by eliminating drum storage, and can be locked to protect your lubricant stock and eliminate cross-contamination of lubcricants.

- Ease of inventory-control

- Sufficient inventory for emergency situations

- Less storage space needed

- Protection of stock; steel tanks can be locked

- Effective quality assuranc; less chance of contamination

- Clean tank with each order

- None of the costs associated with streel drum disposal

Advantages

Lubricant Bulk Tanks | Dry Film Lubricant | Industrial Products | Oven Chain Lubricants | Penetrating Oils | Wire Rope Lubricants | Industrial Products

DRY FILM LUBRICANT

9200 Almasol® Dry Film Lubricant

Spray Lubricant Ensures Long-Lasting Lubrication in Tough Conditions & Broad Temperature Range

Spray Lubricant Ensures Long-Lasting Lubrication in Tough Conditions & Broad Temperature Range

Almasol® Dry Film Lubricant (9200) is a solid film spray lubricant designed for use where permanent lubrication with exceptional long wear life and low frictional properties is desired, and oil and grease cannot be used. For use in a wide temperature range, it combines superior dry film lubrication with safe and easy spray application.

Almasol Dry Film Lubricant provides dependable, long-lasting lubrication in extreme environments where conventional lubricants would be inadequate. It contains a carefully selected blend of Almasol and other solid lubricants of controlled particle size, dispersed in a fast-drying solvent system and resin binder. The resulting film has excellent adhesion.

View Product Information & Technical Data

Lubricant Bulk Tanks | Dry Film Lubricant | Industrial Products | Oven Chain Lubricants | Penetrating Oils | Wire Rope Lubricants | Industrial Products

INDUSTRIAL PRODUCTS

802 Heavy Duty Solvent Degreaser/Brake Cleaner

HDSD is highly effective in removing heavy greases, oil adhesives, lubricants, tar, waxes, asphalt, resins and other heavy materials.

HDSD is highly effective in removing heavy greases, oil adhesives, lubricants, tar, waxes, asphalt, resins and other heavy materials.

FEATURES:

- Dries fast

- Leaves no residue

- Safe on ferrous and nonferrous metals

- Safe on many types of plastics

APPLICATIONS:

- Clean brakes

- Clean engines

- Clean electrical and electronic equipment

- Clean printing equipment

- Clean carburetors

804 H1 SILICONE SPRAY

Silicone-based spray for use as a lubricant with incidental food contact.

Silicone-based spray for use as a lubricant with incidental food contact.

For food plant and other industrial uses.

Silicone-based spray for use as a lubricant with

incidental food contact. May be used on machine

parts and equipment in locations in which there is

potential exposure of the lubricated part to food.

For food plant and other industrial uses.

FEATURES:

- Silicone Lubricant

- Non-staining

- Low odor

- May be used for incidental food contact

- USDA authorized for use in federally inspected meat and poultry plants

APPLICATIONS:

- Food processing equipment

- Food packaging equipment

- Lock mechanisms

- Rubber door and window seals

- Ironing and pressing equipment

- Cutting tables for smooth and even cutting

- Vending equipment

- Molding equipment

- Dry cleaning equipment

2110 Greentastic® Industrial Cleaner

Potent Formula Provides Fast, Effective Industrial Cleanup; Greentastic® Industrial Cleaner is a concentrated liquid solution intended for industrial cleaning uses, including oil and grease.

Potent Formula Provides Fast, Effective Industrial Cleanup; Greentastic® Industrial Cleaner is a concentrated liquid solution intended for industrial cleaning uses, including oil and grease.

Greentastic® Industrial Cleaner is a concentrated liquid solution intended for industrial cleaning uses, including oil and grease. This environmentally friendly water-based formula contains nine carefully selected and blended active cleaning ingredients – almost twice as many as conventional multipurpose products. These powerful ingredients work quickly together to create the different types of cleaning action needed to be effective for a wide variety of industrial applications. Greentastic outperforms conventional non-caustic cleaners. It is not only phosphate-free, but completely phosphorus-free, making it a better choice for the environment.

View Product Information & Technical Data Lubricant Bulk Tanks | Dry Film Lubricant | Industrial Products | Oven Chain Lubricants | Penetrating Oils | Wire Rope Lubricants | Industrial Products

OVEN CHAIN LUBRICANTS

2705 Almasol® Smokeless Chain Lubricant

Almasol® Smokeless Chain Lubricant.

Almasol® Smokeless Chain Lubricant.

Almasol® Smokeless Chain Lubricant (2705) is a premium grade high-temperature chain lubricant. This USDA H2 lubricant is a dispersion of Almasol®, LE’s exclusive solid wear-reducing additive, and other submicron lubricating solids in a special high-temperature food grade synthetic carrier. It is suitable for application to hot chains without interrupting production, and will not smoke at temperatures up to approximately 288°C (550°F).

View Product Information & Technical Data2710 Almasol® Smokeless Chain Lubricant

Environmentally friendly lubricant promotes smooth, long-lasting operation despite extreme heat & moisture.

Environmentally friendly lubricant promotes smooth, long-lasting operation despite extreme heat & moisture.

Greatly reduces wear by completely penetrating pin and bushing area.

Thorough, penetrating lubrication of the pin and bushing areas of oven chains is

of utmost importance in ensuring smooth, efficient operation and long equipment

life. Severe operating conditions, including extreme heat and moisture, can lead to

corrosion and premature equipment failure if lubrication is inadequate.

Other costly side effects resulting from inadequate lubrication include:

- Chain links sticking and strands of chains becoming inflexible

- Chains becoming longer because of rough operation and wear

- Chains jumping off sprockets, contributing to early breakage and failure

- Electrical energy consumption increasing as the amount of friction increases

2799 Almasol® High Temperature Chain Lubricant

Chain lubricant containing Almasol and other sub-micron lubricating solids in a special high-temperature synthetic carrier.

Chain lubricant containing Almasol and other sub-micron lubricating solids in a special high-temperature synthetic carrier.

Designed to maximize lubricant penetration into the pin and bushing area of the chain.

Premium grade, high temperature chain lubricant contains Almasol®, and other submicron lubricating solids dispersed in a special high temperature synthetic carrier. Suitable for application to hot chains without interrupting production operations. When used as directed, the carrier penetrates to all moving parts, leaving a protective film of lubricating solids as it cleanly volatilizes without residue at high temperatures. Will not gum or char, offering maximum migration into chain pins. Reduces frictional drag without building up hard deposits.

View Product Information & Technical Data4061 H1 Ovenworx® Syn Chain Lubricant

Superior Heat Resistance Keeps Oven Chain Operating Freely

Superior Heat Resistance Keeps Oven Chain Operating Freely

Ovenworx® H1 Syn Chain Lubricant (4061) was formulated specifically to combat the demanding conditions present with oven chain applications. In addition, it is approved for incidental food contact and contains no artificial dyes, making it a good choice for food manufacturing plants.

View Product Information & Technical Data9965 Monolec® High Temperature Oven Chain Lubricant

Synthetic H2 Lubricant Penetrates Hot Oven Chains,

Remains Thermally Stable & Reduces Energy Use.

Synthetic H2 Lubricant Penetrates Hot Oven Chains,

Remains Thermally Stable & Reduces Energy Use.

Monolec® High Temperature Oven Chain Lubricant (9965) is a specially formulated lubricant recommended for use on high-temperature oven chains, providing wear protection and lowering power consumption. It is a USDA H2 lubricant made of a synergistic blend of synthetic base fluids and high-performance additives, including Monolec, LE’s exclusive wear-reducing additive. The synthetic base fluids provide excellent thermal stability and low volatility characteristics at high temperatures, while the additives help the lubricant prevent friction, wear and corrosion.

View Product Information & Technical Data Lubricant Bulk Tanks | Dry Film Lubricant | Industrial Products | Oven Chain Lubricants | Penetrating Oils | Wire Rope Lubricants | Industrial Products

PENETRATING OILS

2059 Monolex® Penetrating Oil & Lubricant

Tough General Use Lubricant Works Fast To Dissolve Rust.

Tough General Use Lubricant Works Fast To Dissolve Rust.

Acts rapidly to penetrate and dissolve most rust, gum, and varnish, freeing frozen parts. Leaves a tough film of lubricant and acts as a rust & corrosion preventative on metal surfaces.

Monolex® is a fast-acting, surfacewetting formula that works as a light lubricating oil as well as penetrating lubricant. The tough film created by Monolex is far more effective than ordinary oils. Its excellent penetrating ability helps it work its way through layers of rust, gum, resins, varnish and dirt, dissolving or washing them away and quickly loosening “frozen” components – even those that are hard to reach. Monolex also contains a water-displacing agent that drives out moisture, allowing it to retard corrosion, even in saltwater applications.

View Product Information & Technical Data4058 Quinplex® H1 Penetrating Oil & Lubricant

Available both as a fluid (4058) and as an aerosol (4059), H1 Quinplex® Penetrating Oil & Lubricant is an outstanding food grade lubricant that works quickly to dissolve rust and free up frozen parts. It rapidly penetrates and leaves a heavy lubricant film for further lubrication and corrosion prevention. Formulated with USP grade mineral base oil, this clear, odorless lubricant is NSF H1 registered, and Kosher Pareve and Halal certified for use in food processing equipment. It also contains Quinplex, LE’s proprietary impact-resistant additive.

Available both as a fluid (4058) and as an aerosol (4059), H1 Quinplex® Penetrating Oil & Lubricant is an outstanding food grade lubricant that works quickly to dissolve rust and free up frozen parts. It rapidly penetrates and leaves a heavy lubricant film for further lubrication and corrosion prevention. Formulated with USP grade mineral base oil, this clear, odorless lubricant is NSF H1 registered, and Kosher Pareve and Halal certified for use in food processing equipment. It also contains Quinplex, LE’s proprietary impact-resistant additive.

Formulated from USP Grade mineral oils and other USDA H1 rated components.

4059 Quinplex® H1 Penetrating Oil & Lubricant

Food grade penetrating oil quickly dissolves rust and frees frozen parts. Penetrates and leaves heavy film for lubrication and corrosion protection. NSF H1 certified for food processing equipment.

Food grade penetrating oil quickly dissolves rust and frees frozen parts. Penetrates and leaves heavy film for lubrication and corrosion protection. NSF H1 certified for food processing equipment.

Outstanding food grade, penetrating oil and lubricant. Works quickly to dissolve rust and free-up frozen parts. Rapidly penetrates and leaves a heavy lubricant film for further lubrication and corrosion prevention. Formulated from USP Grade mineral oils and other USDA H1 rated components. Contains LE's proprietary additive, QUINPLEX®.

Formulated from USP grade mineral oils and other NSF H1 registered components. Certified

Halal by IFANCA. Certified Kosher Pareve. Contains Quinplex, LE’s proprietary impact-resistant additive.

Lubricant Bulk Tanks | Dry Film Lubricant | Industrial Products | Oven Chain Lubricants | Penetrating Oils | Wire Rope Lubricants | Industrial Products

WIRE ROPE LUBRICANTS

Self-Healing Fluid Seals & Protects Surfaces

Chain & Cable Greases

Chain & Cable Greases

Wire rope forms an important part of many machines and structures. It is comprised of continuous wire strands wound around a central core. There are many kinds of wire rope designed for different applications. Most of them are steel wires made into strands wound with each other. The core can be made of steel, rope or even plastics.

Wire ropes (cables) are identified by several parameters including size, grade of steel used, whether or not it is preformed, by its lay, the number of strands and the number of wires in each strand.

Years of field experience have shown that wire rope life can be maximized by using the right lubricants combined with the right application method. Companies that have recognized the importance of proper wire rope lubrication and adopted best practices have gained a huge advantage by lengthening wire rope life, eliminating costly replacements and improving safety. Factors that influence wire rope life and performance include type of operation, care and environment. Two problems include wear and corrosion. Wear is accelerated by stress-loading; shock-loading; heavy, jerking loads; or rapid acceleration or deceleration (speed of the cable stopping and starting). Corrosion is caused by fumes, acids, salt brines, sulfur, gases, salt air, and humidity; and can be accelerated by elevated temperatures. The right type and quantity of lubricant will protect the wire rope from degradation, regardless of cause

To learn more about each of the lubricants, click on the photos below

2001 Wirelife penetrates to the core of wire ropes, whether they are running or stationary.

2002 Almasol WireLife Self-Healing Fluid Seals & Protects Surfaces in addition to providing moderate penentration

451 - 453 Almasol Wirelife Tacky Grease Resists Water, Protects Moving Parts and was designed to coat wire rope as well as moving chain and cable parts to ensure long life and smooth, quiet operation

3353 Earthwise LE’s Earthwise™ is a certified Environmentally Acceptable Lubricant (EAL) and is specifically formulated to be earth friendly while still meeting the rigorous demands of industrial applications.

VIPER MKII MID

SUPERIOR PROTECTION OF WIRE ROPESThe release of the Viper MkII provides the same excellent wire rope lubrication performance with the added benefit of a 32% lighter collar and custom built high flow grease pump. Watch the video to see the benefits of the new Viper MkII.

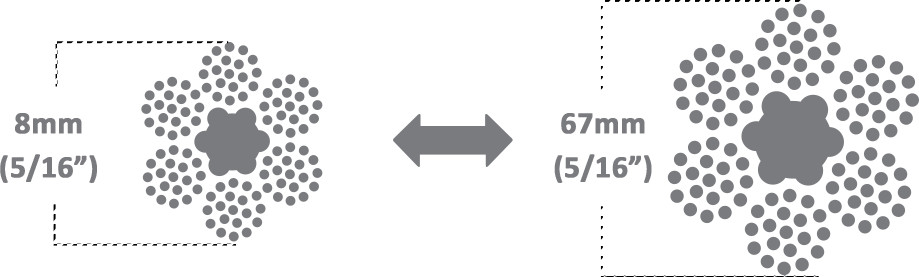

Fast and effective lubrication of wire ropes with a diameter between 8mm to 67mm. The Viper Mid MKII lubricates ropes at up to 2000mt/hour.

Fast and effective lubrication of wire ropes with a diameter between 8mm to 67mm. The Viper Mid MKII lubricates ropes at up to 2000mt/hour.

Recommended for use with Wharf Cranes, Ship Cranes, ROV Cables, Mind Winders, Mobile Cranes, Oil & Gas Platforms, Anchor Ropes, Deck Winches, Overhead Cranes and Ship Loaders.

The Viper Wire Rope Lubricator provides grease penetration, moisture displacement and total coverage by forcing lubricant into the core of the rope.

The Viper MKII Wire Rope Lubricator range provides fast and effective cleaning and lubricating of wire ropes. Wire ropes from 8mm (5/16” ) to 165mm (6-1/2”) in diameter can be automatically greased at speeds up to 2,000mt per hour.

The Viper MKII with the new cast Aluminium collar is 32% lighter and combined with the unique inbuilt carry handles and shoulder strap enables single person wire rope lubrication. Ideal for use on all cranes, towing lines and mooring lines, the Viper MKII eliminates the HS&E risks associated with manual lubrication. Use of the Viper MKII provides improved wire rope lubrication by forcing wire rope lubricant under pressure into the wire rope.

Other lubricators just coat the surface of the ropes but the unique seal design of the Viper wire rope lubricator means the “wire dwell time” in the pressure chamber is up to 80% longer. This longer dwell time means greater lubricant penetration which leads to increased rope life and extended relubrication intervals.

Why use the Viper

CLEAN AND LUBRICATE WIRE ROPES QUICKLY, EFFICIENTLY AND SAFELY WITH THE VIPER MKII SERIES OF WIRE ROPE LUBRICATORS.- Eliminates manual greasing

- Single pass lubrication

- Stops corrosion, protects ropes

- Viper MKII - 8mm (5/16") to 67mm (2-5/8")

- Viper Maxi MKII: 50mm (2") to 165mm (6-1/2")

- Penetrative, displaces moisture from rope's core

- Safer, reduced lubricant usage, less leakage & mess

- Fast, efficient wire rope lubrication

- Reduces downtime, improves equipment availability Custom units available

Common lubricant suffering points for the marine industry include:

Engines - Greases that are subject to heat can melt and run out of bearings. Greases that do not form a good seal can let in contaminants. LE has greases that are extremely tacky and nearly impervious to water washout, and can handle heavy loads with ease. We also offers automatic lubrication systems for making sure grease is applied in the right place at the right time in the right quantity.

Engine oil - If you are looking for longer oil life while still protecting your engine from the demands of the workload, LE can help you safely extend oil drain intervals with our superior, long-lasting engine oils and LEAP oil analysis.

Diesel fuel - Water can get into the fuel of diesel equipment kept outside, causing a loss of power. Injectors get dirty from the buildup of soot. In addition, environmental issues have led to the use of lower performance diesel fuel in on-road and off-road mobile equipment. LE has diesel fuel improvers that address these problems. They can clean up your fuel pumps, injectors and combustion chambers, thereby helping you regain fuel economy, reduce emissions and lower the overall cost per mile or hours of operation.

Wire rope - Do your wire ropes, cables and draglines become rusted, corroded or frayed? You can protect your wire rope and cable from high stress loading, shock loading, jerking and heavy loads with LE's full line of penetrating and coating wire rope lubricants. Whether you want lubricant to penetrate to the core or to coat and seal, LE has a full range of protective lubricant solutions, including wire rope lubricant applicators to reduce labor costs and ensure safe, reliable operation.

Difficulties with maritime lubrication

Although ship building involves some unique processes, component manufacturing is not dissimilar to other manufacturing industries. The difficulty in marine lubrication comes with maintenance procedures. In such a busy industry most ships don’t get much time to rest, and maintenance is done mid-voyage, with machinery operating. The equipment can be in hazardous locations and often exposed to the brutal forces of nature. Add violent rocking to the list and maintenance procedures can be hazardous.

New Extended Warranty: Documented use of LE452, LE453 Wirelife™ Almasol Wire Rope Lubricant or Earthwise™ EAL Wire Rope Lubricant will double the Viper warranty period to 24 months.

2001 Wirelife® Monolec® Penetrating Lubricant

Versatile, Wear-Reducing Oil Preserves Metal to the Core

Versatile, Wear-Reducing Oil Preserves Metal to the Core

Penetrating lubricant supplies superior load capacity and corrosion resistance. Solvent enhances penetration. When solvent evaporates, a thin film remains to protect and lubricate each strand. Excellent for chains.

Wirelife® Monolec® Penetrating Lubricant (2001) has excellent corrosion resistance and high load carrying (EP) properties. It penetrates to the core of wire ropes, whether they are running or stationary. It is also excellent as a penetrating lubricant for chains of all sizes and works well in a variety of other industrial applications. When used in conjunction with Wirelife Almasol® Coating Lubricant, maximum protection and wear reduction is achieved.

It contains a petroleum solvent to enhance its ability to penetrate. The solvent evaporates, leaving behind a film of heavy-bodied lubricant that protects and lubricates each strand and resists leakage from the wire rope core.

2002 Wirelife® Almasol® Coating Wire Rope Lubricant

A fluid coating wire rope lubricant that provides a self healing film to reduce wear and corrosion under extreme load and moisture. It penetrates into the core of running wire ropes to provide protection against fretting corrosion, wear and rust.

A fluid coating wire rope lubricant that provides a self healing film to reduce wear and corrosion under extreme load and moisture. It penetrates into the core of running wire ropes to provide protection against fretting corrosion, wear and rust.

Wirelife® Almasol® Coating Lubricant (2002) is a fluid wire

rope lubricant that provides a tough outer coating to seal

and protect against fretting corrosion, wear and rust – even

under extreme load and moisture. It seals and protects

better than any product available. When used in conjunction

with Wirelife Monolec® Penetrating Lubricant, maximum

protection and wear reduction is achieved.

In addition to its primary function as a coating, it also

provides moderate penetration – depending on the tightness

of tolerances and the temperature when applied. It contains

a petroleum solvent to enhance its ability to penetrate. The

solvent evaporates, leaving behind a self-healing, nontacky,

protecting film that is highly resistant to wash-off from both

fresh and salt water.

2011 Wirelife® LowTox® Penetrating Oil

Highly penetrating lubricant with excellent load-carrying capability. Designed for marine and other sensitive applications that require a low-toxicity wire rope and chain lubricant. Provides outstanding protection against rust, while having the lowest possible toxic effect on the environment.

Highly penetrating lubricant with excellent load-carrying capability. Designed for marine and other sensitive applications that require a low-toxicity wire rope and chain lubricant. Provides outstanding protection against rust, while having the lowest possible toxic effect on the environment.

Designed for marine environments and other applications where environmental concerns require the use of a very low toxicity wire rope and chain lubricant, LE’s Wirelife® Low Tox® Penetrating Lubricant (2011) has excellent load-carrying capability and provides outstanding protection against rust, while having the lowest possible toxic effect on the environment.

2022 Wirelife® Almasol® Syn Coating Lubricant

Synthetic oil provides ultimate surface protection. An extremely tacky, nonasphaltic synthetic lubricant with exceptionally high film strength.

Synthetic oil provides ultimate surface protection. An extremely tacky, nonasphaltic synthetic lubricant with exceptionally high film strength.

Perfect for extreme environments and conditions, it is the ultimate outer surface protector for wire rope and cable and comes from the same advanced technology that LE developed to protect large open gears in the mining and quarry industries. It derives its high load-carrying capacity from its synergistic blend of an extreme pressure additive and Almasol®, LE's exclusive wear-reducing additive.