- Home

- Lubrication

Systems - Lubricants

& Fluids - Lubrication

Equipment - Contamination

Control - Condition

Monitoring - Services &

Training

![]()

Lubrication Technologies

Your Professional Lubrication Management Team.

Lubrication Technologies, Inc.

120 BOSWORTH ST.

WEST SPRINGFIELD • MA 01089

August 25, 2016

ILC AUTO LUBRICATION PROGRESSIVE SINGLE-LINE SYSTEMS

ILC Auto Lubrication Series Progressive Single-line Systems

ILC MAX SYSTEMS

ILC MAX SYSTEMS

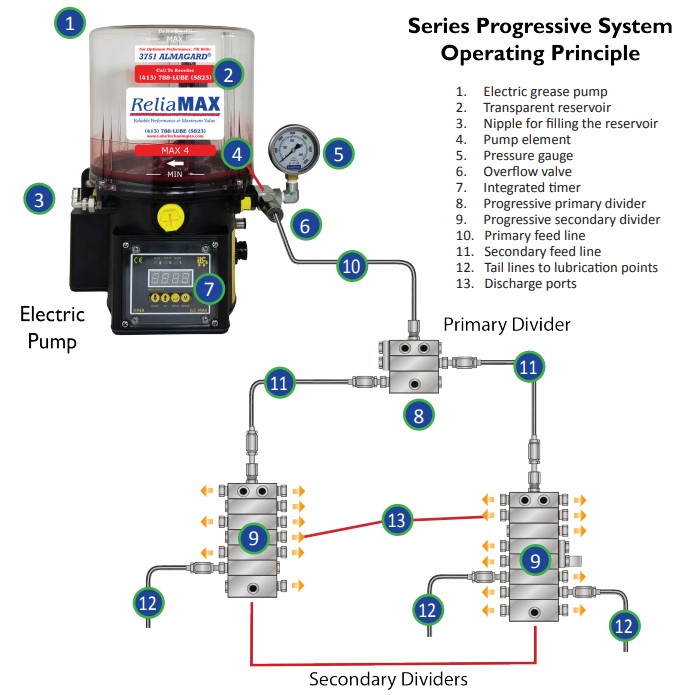

The progressive lubrication systems allow oil or grease (up to NLGI 2) distribution to lubricate the friction points of the machines. The divider blocks of between 3 and 24 outlets guarantee a correct discharge for each point. The system is easy to control and can be monitored by an electrical switch on the main divider.

Ideally suitable for the automatic grease lubrication of all types of industrial machines and as a chassis lubrication pump for trucks, trailers, buses, construction and mechanical handling vehicles.

In conjunction with ILC DPA, DPM or DPX progressive dividers, more than three hundred greasing points can be automatically centralized from just a single grease pump.

The pumps are designed for intermittent or continuous operation to provide regular pre‐programmed lubrication cycles as required for the various applications.

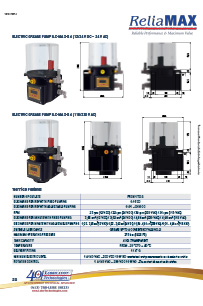

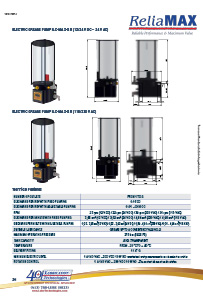

A direct‐mounted electric geared motor drives an internal rotating cam, which can actuate up to three externally mounted pump elements. Every pumping element has a relief valve to protect the system against over‐pressure.

To have a bigger discharge it is possible to collect the three outlets from the pumping elements together in a single tube.

ILC SERIES PROGRESSIVE LUBRICATION SYSTEMS

ILC Max G2, G4, G5 and G8 - Grease and Oil Series Progressive Electric Pumps

These reliable, comprehensive and customizable centralized lubrication systems offer 3 types of progressive dispensing in combination with manual pumps or automatic pumps. ILC progressive series lubrication systems can be configured for oil or grease (up to NLGI 2), are easy to control and monitor and operate efficiently in the extreme environments found around industrial machinery and fleet operations.

These reliable, comprehensive and customizable centralized lubrication systems offer 3 types of progressive dispensing in combination with manual pumps or automatic pumps. ILC progressive series lubrication systems can be configured for oil or grease (up to NLGI 2), are easy to control and monitor and operate efficiently in the extreme environments found around industrial machinery and fleet operations.

Designed for intermittent or continuous operation, the direct mounted electric gear motor drives an internal rotating cam controlling up to three externally mounted pump elements, each of which with a maximum operating pressure of 250 bar and each will dispense up to 2.88 cc/minute (a larger discharge can be achieved by combining two or more outlets to one externally mounted pump. Each pump has a relief valve to protect against over-pressure. The internal drive shaft is coupled to a paddle which ensures continuous priming of the pump(s) with grease up to NLGI 2 at ambient temperatures down to -20°C.

The electric gear motor is protected with an IP-56 rated Nylon/Fiberglass enclosure and the seal is guaranteed with well mounted "o"-ring.