- Home

- Lubrication

Systems - Lubricants

& Fluids - Lubrication

Equipment - Contamination

Control - Condition

Monitoring - Services &

Training

![]()

Lubrication Technologies

Your Professional Lubrication Management Team.

Lubrication Technologies, Inc.

120 BOSWORTH ST.

WEST SPRINGFIELD • MA 01089

August 25, 2016

ILC LubeTool Lubrication Systems

Micro-Lubrication & Cooling Systems

Lubrication Technologies is pleased to announce the Lubetool lubrication system, developed by ILC, that provides micro lubrication for chains in all types of applications.

Lubrication Technologies is pleased to announce the Lubetool lubrication system, developed by ILC, that provides micro lubrication for chains in all types of applications.

Typically chain lubrication involves drip or pump feed to brush or spray nozzles with lubrication intervals controlled with timers or electric solenoids. The downside of these type of systems is that the quantity of lubricant supplied often means excess lubricant drips off the chain. Also an issue can be the electrics required need to be enclosed in IP65 rated enclosures due to the sometimes-harsh operating environments.

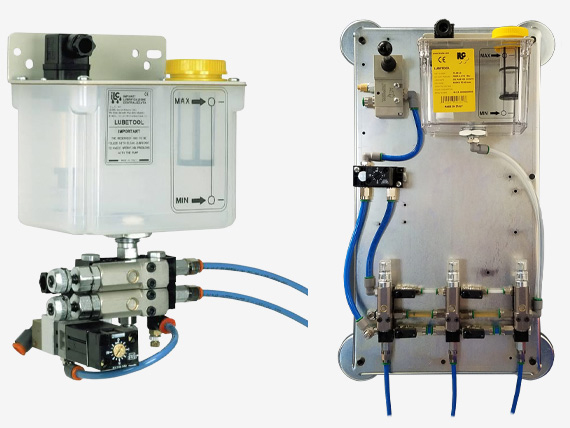

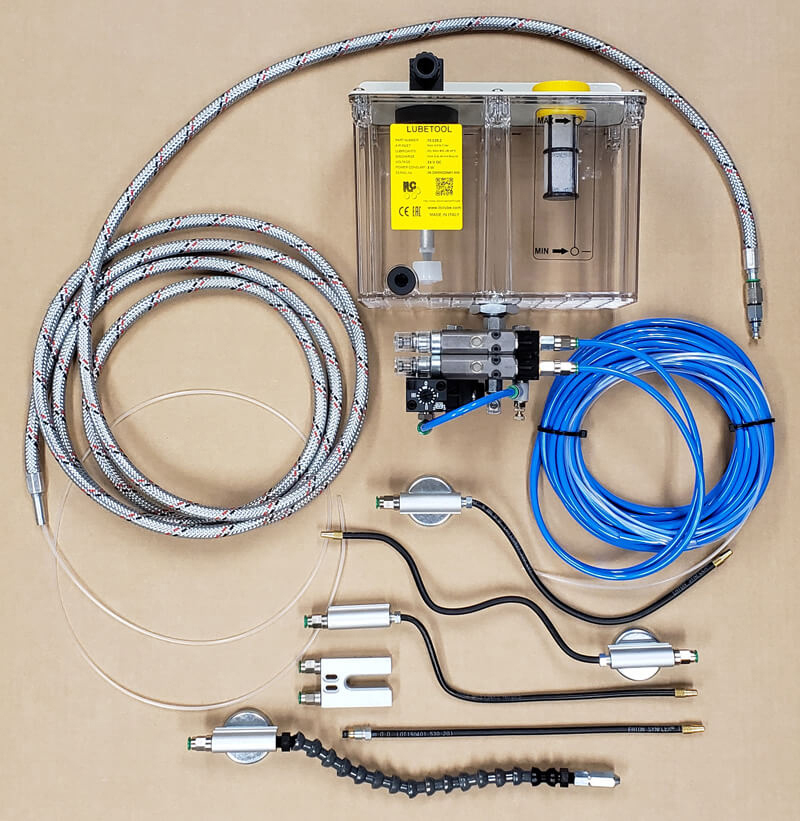

The ILC LubeTool system successfully installed in numerous applications incorporates a reservoir, air operated pulse timer operating oil / air injectors. When air is turned on either manually or via a solenoid valve the pulse timer sends micro pulses to the injectors, which then inject minute quantities of lubricant from 0 to 41 cubic millimeters per stroke into the air stream leading to the spray nozzles. The amount of lubricant delivered each pulse is so small as to be invisible to the naked eye, however over a short period of time it provides more than adequate lubrication for the chain while not dripping or slinging off.

Systems can be designed in modular format from one spray up to 8 (per package), coaxial tube lengths from the injector to the spray nozzle can be up to 10 metres meaning the system can be installed remotely from the chain application. A typical 4-point spray system can be designed and installed at an extremely cost effective price when measured against the cost and inefficiencies of manual lubrication of chains.

Applications

- Tapping, Drilling, Boring, Broaching

- Milling and Engraving

- Circular saws, Band saws

- Stamping, Bending, Rollforming

- Pipe bending, Metal spinning

- Chain lubrication

- Conveyors

ILC LubeTool Sawblade & Chain Oiler

In every phase of industry, chains will be found transmitting power and conveying raw materials or finished goods with efficiency and dependability. The dependability of chain operation depends upon the basic principles of good installation, proper lubrication and maintenance. Other points to consider are the OH&S and loss of production issues associated with keeping chains properly lubricated but not over lubricated.

Lubrication Technologies also carries a comprehensive range of high performance Specialty Lubricants that can be recommended for each application. High temperature, water resistant and food grade products are all available to ensure that chains receive the ideal lubricant at the right time in the right quantities.

LubeTool Unit

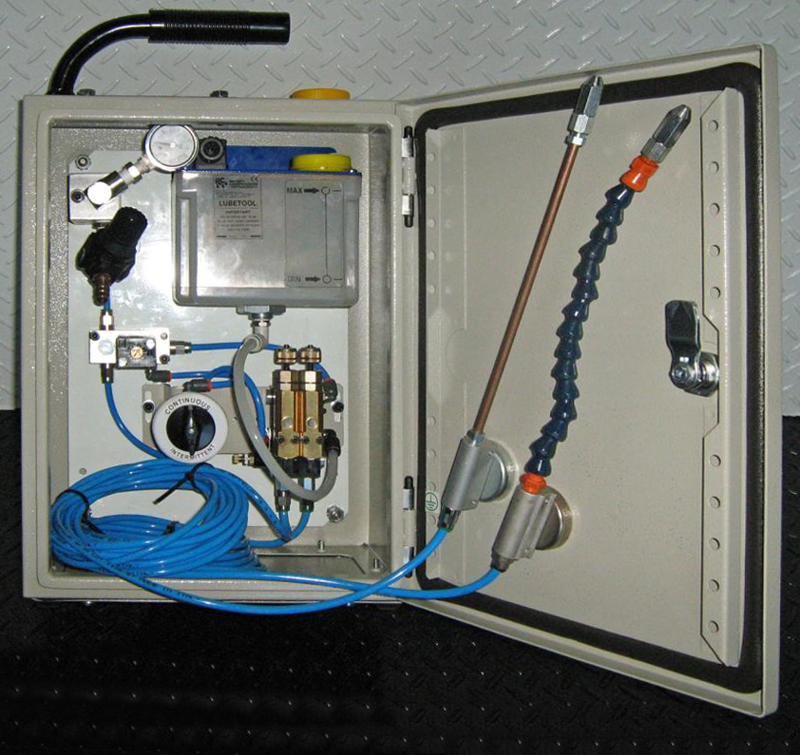

Lubrication Technologies is well aware that many customers have tried chain lubrication systems and been disappointed. Therefore they have developed a transportable Lubetool demonstration unit which can be quickly and effectively put into service at a customer facility.

The unit has two spray nozzles one rigid and the other flexible both with magnetic bases that can be mounted to machinery. The Lubetool demonstrates lubrication method in two ways either by injecting oil into a continuous air stream or pulsing air/oil simultaneously simply by turning the valve. The speed of the spray pulse can be controlled via the pulse generator and can cycle in excess of two times per second.

The unit is enclosed in a steel enclosure for secure transportation and can be connected up to an air supply and demonstrated in a matter of minutes.

The LubeTool Unit is available for rental evaluation with a deposit, customer pays shipping both ways. For more information, please call (413) 788-5823.

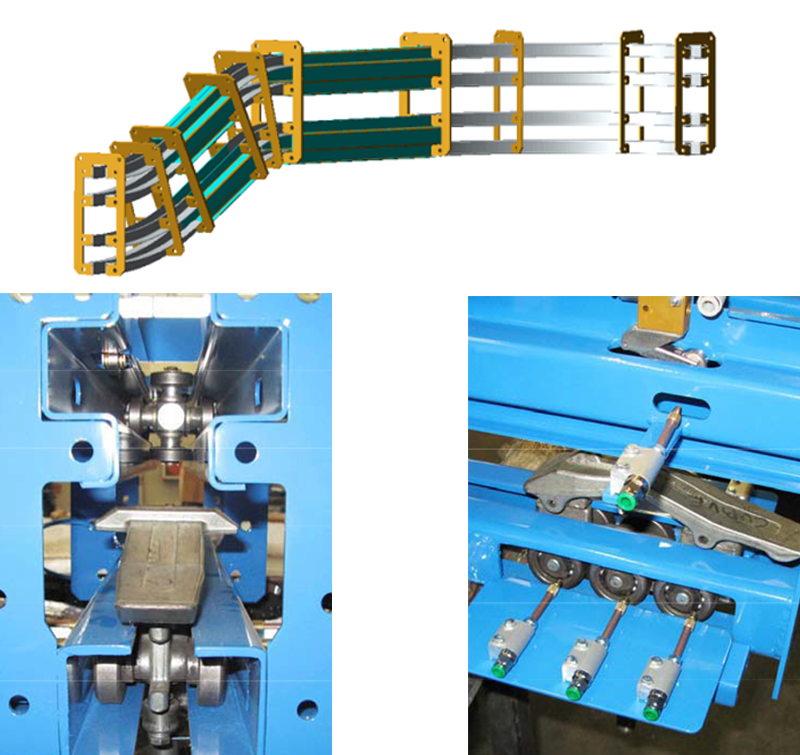

Overhead Conveyor Lubrication System

Designed to lubricate the rollers of conveyors while in operation, this system delivers a metered amount of lubricant into moving bearing fittings. The custom engineered lubrication systems are perfect for industrial machinery applications, even in the harshest operating conditions. Each conveyor requires one unit for the left side and one unit for the right side. The sequence of the lubrication events (each roller or every other roller, etc.) depends on the number of rollers, the speed of the conveyor or the distance between the rollers.

View Overhead Conveyor Lubrication System (PDF) for more information.