- Home

- Lubrication

Systems - Lubricants

& Fluids - Lubrication

Equipment - Contamination

Control - Condition

Monitoring - Services &

Training

![]()

Lubrication Technologies

Your Professional Lubrication Management Team.

Lubrication Technologies, Inc.

120 BOSWORTH ST.

WEST SPRINGFIELD • MA 01089

August 25, 2016

Lubrication System Fittings

Known for our high quality standards, the Lubrication Technologies Shop is the "go to" for automatic lubrication system fittings and hose lines. Our online store offers a diverse range of screw fittings for all kinds of central lubrication configurations.

Known for our high quality standards, the Lubrication Technologies Shop is the "go to" for automatic lubrication system fittings and hose lines. Our online store offers a diverse range of screw fittings for all kinds of central lubrication configurations.

In certain scenarios, assets that are worth millions depend on one single bearing and in all configurations where moving parts must be protected from direct frictional contact and be kept movable and flexible, that's where our fittings come into play.

Central lubrication systems keep bearings movable - that is our mission!

The fields of application are diverse, the list below mentions some of the equipment serviced.

- Construction machinery: wheel loaders, excavators, concrete pumps

- Agricultural machinery: combine harvesters, potato harvesters, maize choppers, grape harvesting machines

- Industrial plants: filling systems, wind power plants, paper mills

- Utility vehicles: lorries, municipal vehicles, dump trucks, excavators

- Compression Fittings

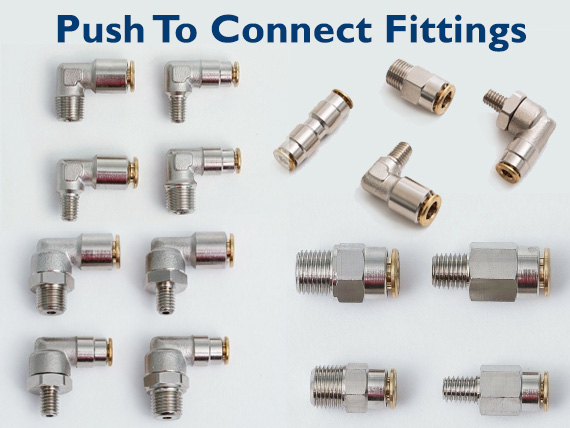

- Push To Connect Fittings or Push-in Fittings

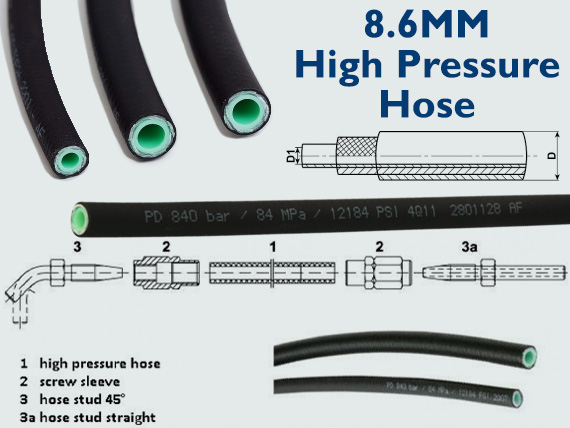

- Threaded Hose Sleeves for Reusable Ends or Screwsleeves

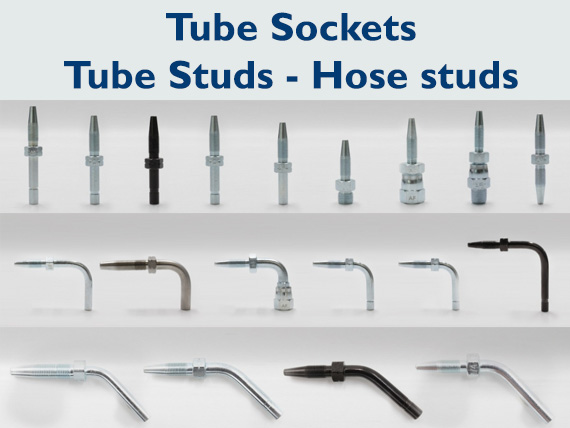

- Tube Sockets - Tube Studs - Hose studs - Male Stand Pipes

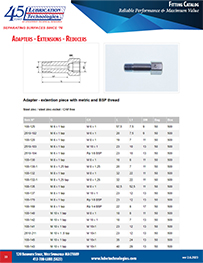

- Adapters - Extensions - Reducers

- Hoses & Tubing

The fittings for central lubrication are subject to continuous detail improvement. For us, continuous adjustment and adaptation to global developments in the lubrication engineering industry is also one of our most valuable activities.

The quality of details is what facilitates assembly for our customers and increases the longevity of our products for end users.

In our capacity as efficient producer and supplier, we have been delivering fittings to both manufacturers and industrial organizations, as well as workshops, municipal services, etc. all over the world for more than 25 years.

Regardless of whether you work with automated or manual central lubrication systems or use lubrication aids for individual areas - we have the right solution for you!

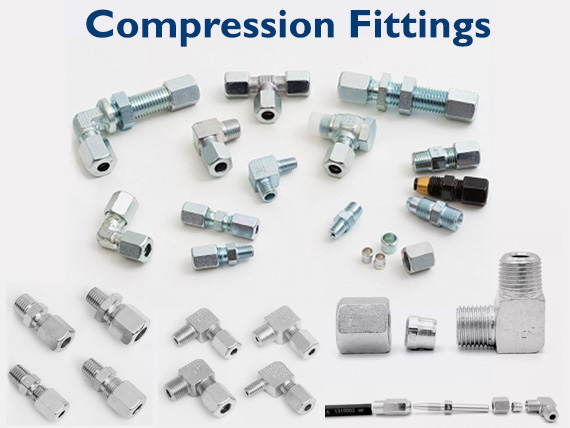

Compression Fittings

For pumping oil and grease through tubes, tubing systems, plastic tubes and hose lines, compression fittings are required for properly connecting and combining the different tubes and hoses with one another. The systems obtained in this way are characterized by high degrees of tightness and compression strength.

For pumping oil and grease through tubes, tubing systems, plastic tubes and hose lines, compression fittings are required for properly connecting and combining the different tubes and hoses with one another. The systems obtained in this way are characterized by high degrees of tightness and compression strength.

Compression fittings for regular applications are available in the following designs, among others: steel 1.0718, 1.0402, carbon 20 or 45 (both with chromium-6-free galvanized surfaces)

On the other hand, compression fittings made of high-grade stainless steel (1.4401/1.4571 material) are components that are well suited for application in the food processing industry, in the beverages industry but also in marine and harbor applications and other wetland areas. The reason is that stainless steel is a neutral and highly chemically resistant type of material.

To ensure proper specification, quality and rationalization during installation and use of the compression fittings, the production process is subject to special quality certification according to EN ISO 8434 and DIN 2353 standards. Compression fittings generally comprises a stud with a 24° cone, a coupling nut according to DIN 3870 and a compression fitting according to DIN 3861 shape A or DIN 3861 shape B.

The studs used in compression fittings are equipped with both a screw-in thread (available in different sizes) and an external thread with W bore shape according to DIN 3861, with an incorporated 24° cone. The coupling nuts are also equipped with metric threads; depending on the design and tube diameter, these threads are available in different sizes. In order to ensure the extremely high sealing performance required, the cutting rings are also equipped with a 24° cone.

In this context, for specification of the operating pressure, it must be taken into account that the burst pressure for compression fittingss is significantly higher than the operating pressure.

The major benefit of state-of-the-art compression fittings is the ease of assembly that the systems provide. Compression fittings are suitable for installation into the most varied processes and are the most widely used screw fitting components. Retention of the tube or hose is ensured by the cutting ring in a crimped connection. Connections using compression fittings are most frequently used with plastic tubes, metal tubes, and hose systems. Our compression fittings can be used for grease central lubrication systems or viscous oil supply systems.

Push To Connect Fittings

Push Locks - Push To Connect Fittings or Push-in Fittings

Push Locks - Push To Connect Fittings or Push-in Fittings

The pressure range is greatly influenced by the hoses and tubes used and by the ambient temperature.

Instructions for assembly and disassembly of our push-in fittings

Assembly using plastic tubes

1. Cut and deburr the plastic tube at 90° using a hose cutter.

2. Make sure to prevent any oval deformation of the tube.

3. Insert the tube into the push-in fitting to the stop (the plastic tubes from our range are equipped with marks that make it easier to insert them by the correct length).

ASSEMBLY USING HIGH-PRESSURE HOSES

1. Assemble the screw-in socket (left-hand thread) onto the end of the hose.

2. Screw-in the tube stud with claw groove.

3. Apply the push-in fitting onto the tube stud. The O-ring of the plug-and-socket screw connection ensures a tight seal.

As a general rule, during assembly of push-in fittings, it must be ensured that the hose connectors are not subject to tensile loads. If tensile loads act on a push-in screw fitting, this may encumber or prevent loosening the disconnection ring during disassembly. The disconnection ring of a push-in fitting may cant if the specified bending radius of the plastic tube or the high-pressure hose is not complied with.

Disassembly

By pressing the disconnection ring of the push-in screw fitting and simultaneously pulling the plastic tube or the tube stud, the plastic tube / high-pressure hose can be disassembled.

As a distributor of fittings and various accessories for central lubrication engineering, We stock the largest assortment of sizes to meet the demand for connection technology for central lubrication systems.

The range of fittings in the field of plugged fittings or push-in fittings is available from Lubrication Technologies, Inc.

Products NOT intended for household applications and must only be installed by trained personnel.

Please remember that our trained and qualified staff of Lubrication Technologies is always prepared to provide help and advice with regard to all technical aspects prior to, during, and after installation.