- Home

- Lubrication

Systems - Lubricants

& Fluids - Lubrication

Equipment - Contamination

Control - Condition

Monitoring - Services &

Training

![]()

Lubrication Technologies

Your Professional Lubrication Management Team.

Lubrication Technologies, Inc.

120 BOSWORTH ST.

WEST SPRINGFIELD • MA 01089

nOVEMBER 16, 2022

Groeneveld-BEKA - Interlube Automatic Lubrication Systems

Lubrication Technologies, Inc. is an Authorized Groeneveld-BEKA Distributor of the Groeneveld - Interlube System Parts

With the Groeneveld-BEKA centralized automatic lubrication systems, your cost per mile (the key indicator for vehicle costs) is significantly reduced. As an Groeneveld-BEKA Distributor, Lubrication Technologies is more than able to supply Autolube Systems for a wide variety of applications.

With the Groeneveld-BEKA centralized automatic lubrication systems, your cost per mile (the key indicator for vehicle costs) is significantly reduced. As an Groeneveld-BEKA Distributor, Lubrication Technologies is more than able to supply Autolube Systems for a wide variety of applications.

These systems are particulary suited for installation by the end user. We can support you or your personnel on the various details we have learned resulting n a reliable and durable installation. For more information contact Lubrication Technologies at (413) 788-5823.

Catalogs, Installation Manuals & Diagrams (Click on Thumbnail to Download PDF)

In a multi-line system, grease is led directly from the injectors in a pump through their own pipes to a lubrication point. View more by clicking on the thumbnail.

MultiLine SFi self-fit industrial kit enables the use of automatic lubrication on conveyor belts, bearings, chains and gears. The simple-to-install kit it comes in a single box with everything you need for most light industrial applications. Simple. Multiplied.

The A-Series consist of a range of oil lubrication pumps for use in a multi-line system.The pumps in the A-Series are the central element of a multi-line oil lubrication system. Different oil containers can be individually attached to the pump.

Pumps in the A-Series serve up to 12 lubrication points with one pump. View the Parts Diagram

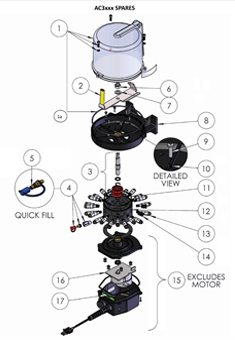

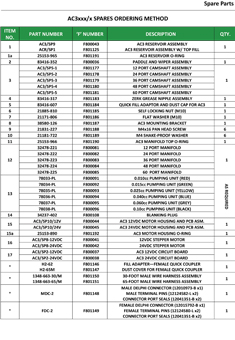

Multi Line A3 Spares Ordering Method List