- Home

- Lubrication

Systems - Lubricants

& Fluids - Lubrication

Equipment - Contamination

Control - Condition

Monitoring - Services &

Training

![]()

Lubrication Technologies

Your Professional Lubrication Management Team.

Lubrication Technologies, Inc.

120 BOSWORTH ST.

WEST SPRINGFIELD • MA 01089

August 25, 2016

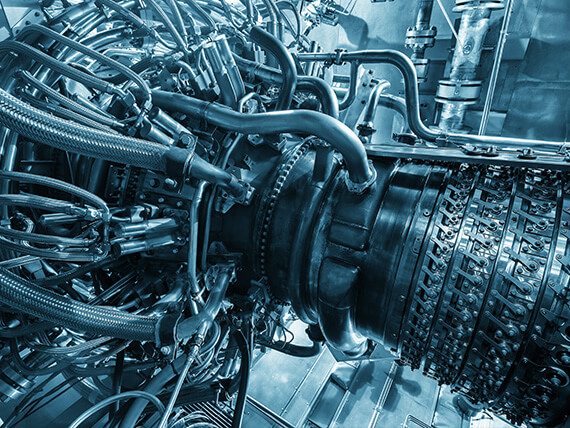

Turbine Power Generation - Automatic Lubrication Systems

POWER UP FOR RELIABILITY-CENTERED SAVINGS

Reliability Centered Maintenance, is the approach endorsed by Maintenance Professionals across industries. We practice RCM to support the protection of assets at the lowest life-cycle cost. Our World Class Lubrication Reliability Program incorporates best practices and produces optimum results.

Reliability Centered Maintenance, is the approach endorsed by Maintenance Professionals across industries. We practice RCM to support the protection of assets at the lowest life-cycle cost. Our World Class Lubrication Reliability Program incorporates best practices and produces optimum results.

For machinery to run efficiently, they depend on the type of lubricant selected as well as the method of application. Modern machinery requires exact methods of application, unlike when lubrication could be applied by hand, today it needs to be precisely controlled. For most machinery, different methods of lubrication and types of lubricants must be employed for different parts with either a grease or oil lubricant.

Whatever your lubrication needs, Lubrication Technologies, Inc. (LTI) can help

Extreme pressure, high temperature, continuous high speed, and contamination from dirt and moisture are all conditions that can create strenuous demands on the lubrication systems protecting valuable production assets. LTI can help you create and implement a customized lubrication reliability program that protects your equipment and keeps it contaminant-free. LTI's RCM program can deliver quantifiable performance advantages to rubber and plastic manufacturing operations of all types and sizes.

Proper lubrication + contamination control = profits

It makes sense. The number one cause of failures is contamination of hydraulic oils and lubricating oils with dirt and water. If we can limit the size of particulates that enter oil reservoirs to smaller than the film of oil we are counting on to run interference between two opposing moving metal parts, then we can accomplish the following:

- Lengthen lifespan of parts, equipment and lubricant

- Increase time between failures / increase production

- Reduce friction, heat and wear

- Reduce energy consumption

- Reduce oil temperatures

- Increase oil change intervals /decrease waste oil / decrease new oil purchases

- Increase profits

Lubricant Handling / Storage Contamination Control

- Keep it Clean-Cool-Dry

- Desiccant Breathers

- Color Coding

- Storage Solutions

- Personnel Training

- Monitor / Improve

Common lubricant suffering points for modern machinery operations include:

Bearing failures - Greases that are subject to heat can melt and run out of bearings. Greases that do not form a good seal can let in contaminants. Lubrication Engineers has greases that are extremely tacky and nearly impervious to water washout, and can handle heavy loads with ease. We also offer automatic lubrication systems for making sure grease is applied in the right place at the right time in the right quantity.Wire rope - Do your wire ropes, cables and draglines become rusted, corroded or frayed? You can protect your wire rope and cable from high stress loading, shock loading, jerking and heavy loads with LE's full line of penetrating and coating wire rope lubricants. Whether you want lubricant to penetrate to the core or to coat and seal, LE has a full range of protective lubricant solutions, including wire rope lubricant applicators to reduce labor costs and ensure safe, reliable operation.

PRESENTATIONS & ARTICLES

Here is a small portion of our Case Studies, Articles, White Papers, Presentations and more. Are you curious about how things work? If so, then Click to View More!

-

Lube Tech Presentation

Marine/Shipping Applications -

ME - july/aug 2010

Emerging Problem of lubricant Varnish -

Baldor Motor Maintenance

MSSM0274AR/9731AV - Maintenance Manual -

Reprint: Global Cement Mag. oct 2007

Motor Bearings - ABB Switzerland -

TLT: Best Practices jan. 2010

Managing Lubricant Degradation -

UpTime: june/july 11

Automatic Lubrication Systems - Don't Work!?!