- Home

- Lubrication

Systems - Lubricants

& Fluids - Lubrication

Equipment- GREASE PUMPS-Electric (Yamada)

- GREASE PUMPS-Air More--->

- GREASE GUNS More--->

- Quick Release Grease Coupler (Meclube)

- OIL PUMPSMore--->

- HOSE AND REELS More--->

- LUBRICATION CARTS

- Engine Crankcase DRAINS

- USED OIL DRAINS (Samson)

- XPEL OIL CONTAINERS

- BULK STORAGE SYSTEMS More--->

- Lube System Filling Options

- Showcase

- Contamination

Control - Condition

Monitoring - Services &

Training

![]()

Lubrication Technologies

Your Professional Lubrication Management Team.

Lubrication Technologies, Inc.

120 BOSWORTH ST.

WEST SPRINGFIELD • MA 01089

August 25, 2016

NTF (formerly NTZ) BYPASS FILTRATION

For over 35 years, NTF (formerly NTZ) have designed, manufactured and marketed highly efficient oil filtration products. Their products are used by companies throughout the world to achieve better performance in their equipment, to minimize waste and acheive significant savings in maintenance costs.

For over 35 years, NTF (formerly NTZ) have designed, manufactured and marketed highly efficient oil filtration products. Their products are used by companies throughout the world to achieve better performance in their equipment, to minimize waste and acheive significant savings in maintenance costs.

The NTF (formerly NTZ) filter system range has been continually developed to guarantee the most efficient filtration of engine lube oils, transmission fluids or hydraulic oil using ultra-effective filter media to obtain the highest cleanliness standards. Whether it’s a bypass micro filtration system for an engine, transmission or power steering application, or a hydraulic filtration system for an industrial or mobile application, there’s an NTF® (formerly NTZ®) filter system solution. These functions can only be realised by the application of the unique concept of NTF high efficiency micro filtration systems.

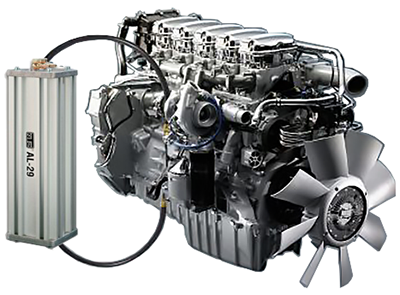

NTF® (formerly NTZ®) AL SERIES

- Heavy-Duty Trucks

- Construction and Off-Highway Vehicles

- Agricultural Equipment

- Marine

- Hydraulic

- Engine Oil

- Transmission Fluid

- Powershifts

The AL filter systems are equipped with a restriction in order to prevent the oil pressure to drop beneath the required minimum as a result of the created bypass.

NTF® (formerly NTZ®) OFFLINE FILTER SERIES

- Steel Industry

- Paper Industry

- Plastics Industry

- Petro Chemical Industry

- Maritime Industry

- Windmills

- Injection Molding Machines

- Motor Oil in Ship and Stationary Engines

- Hydraulic Aggregates

- Hydraulic

- Engine Oil

The NTF® (formerly NTZ®) Off Line Filter System is based on a modular and specially designed manifold that integrates all of the oil channels. So leakages from vibrations or poorly connected pipes are a thing of the past. Because the whole system is mounted on a base plate, it can be quickly and easily installed in your system.

NTF® (formerly NTZ®) G-125 & G-245

- Industrial

- Maritime Industry

- Large Oil Sumps

These systems are build to order and are equipped with their own motor-pump combination, which means that the system pressures and specifications remain in conformance with the values specified by the manufacturer. The motor-pump combination pumps oil from the reservoir (or engine sump), the dirty oil is then pumped through the filter and clean oil is returned to the reservoir.

HOW MICRO FILTRATION WORKS

Technology

Technology

NTF® (formerly NTZ®) Nederland BV is leader in micro filtration technology, having worked in micro filtration for several decades. We develop each OE and aftermarket filter application to very exacting standards, based on vehicle performance requirements, usage and environment.

Ultra-high efficiency bypass micro filtration utilizes a secondary circuit that combines bypass and micro filtration. Micro filtration provides additional filtering efficiency to the primary filtering system. NTF's® (formerly NTZ®) filtration system utilizes patented compression technology in combination with depth media to ensure the highest filtration efficiencies. The key to our superior filtration technology is in our filter element. The radial flow through the element offers a larger filtration surface area that prevents the channelling effect of filter elements design in a "honeycomb" style. This larger surface area holds more dirt and provides a more efficient filtering process. Click here to see our Radial vs Axial Filtration comparison.

Technology

While full fluid filtration is a common practice, ultra-high efficiency micro filtration is very successful at cleaning partial flow of fluid to a very high level at one time. Over a short period of time, all of the fluid reaches a superior cleanliness level. When applied to lubrication fluids for all types of machinery, including internal combustion engines, automatic transmissions or hydraulic systems, the NTF® (formerly NTZ®) system improves fluid and system performance.

During the bypass process, an average of 1-2 liters/minute of fluid (vs. 10-20 liters/minute in a full flow filter) passes through the filter, with no inline pressure drop and no need for a bypass valve. Because of the lower flow rate, the bypass system can be more restrictive, and able to remove a 99% of the very smallest particles in the fluid. Learn more about the installation process by viewing these slides. Micro filtration results in superior fluid cleanliness for any lubrication or power transmission fluid system, including automatic transmission fluid (ATF), continuously variable transmission fluid (CVTF), dual clutch systems, engine oils, power steering fluids and hydraulic oils.

Who is NTF?

NTF, while under a new name,has a long, successful history in the filtration industry. NTF was purchased from NTZ International B.V. in the Netherlands in January 2017 and continues to offer the same products. We provide a variety of high performance filtration products for automotive original equipment, industrial, off-road, construction, fuel, hydraulics, engine and agricultural. We have the added services of developing and specifying filter medias to suit your specific application and system’s cleanliness requirements.

What types of products do you produce?

NTF produces bypass and inline micro filtration systems for engine and transmission application throughout the industrial and transportation industries. Our products are applicable to several markets:

Automobile and light trucks

Heavy-duty vehicles (including trucks, off-highway, agricultural, etc.)

Fleet operations (both heavy-duty and passenger car)

Marine engines

Aerospace

Industrial (including such varied products as heavy-duty equipment, static simulation equipment, parts manufacturing equipment, windmills, steel industry equipment and paper and lumber industrial applications)

What is micro filtration?

Ultra-high efficiency filtration filters down to a submicron level leading to an overall cleanliness level superior to normal fuel flow filtration. The filtration system utilizes patented compression technology in combination with depth media to ensure the highest filtration efficiencies.

What is the difference between micro filtration and standard filtration?

Every engine and automatic transmission is equipped with a standard, or full flow filter, which removes the large particles that could cause immediate damage to vehicle systems. But because an adequate flow of fluid through the filter must be maintained, the element has to be permeable, resulting in a filtering of particles no smaller than 10 to 15 micron.

However, the majority of contaminants are much smaller than 10 micron, and they can easily pass through a standard filter. Bypass filtration is necessary to filter out 5-10% of fluid flow, thus avoiding any counter pressures caused by placing additional filtration directly into the oil circuit.

What are the benefits of micro filtration?

Micro filtration results in superior fluid cleanliness for any lubrication or power transmission fluid system, including automatic transmission fluid (ATF), continuously variable transmission (CVT) fluid, dual clutch systems, engine oils and hydraulic oils. Overall, micro filtration results in fewer malfunctions, reduced downtime, reduction of waste oil and increased equipment life.

Why do I need additional filtration (other than factory equipped)?

Factory full flow filters are designed to provide a minimum screening of particulates (15 micron or larger particles of soot and carbon) to keep ongoing bearing protection and still maintain a specified flow rate, but in turn it loses a considerable amount of oil cleanliness. Ninety percent of engine wear is from particulates between .5 and 2.0 micron in size. The NTF filtration system removes contamination particulates down to .5 micron in size. The reason for adding the NTF filter to your existing system is to clean the lube oil, allowing the engine to run on clean oil 100% of the time. By keeping the oil clean you are eliminating over 90% of most engine wear.

Does additional filtration take care of coolant dilution?

Excessive coolant contamination within an engine can occur with gasket leaks and cracks in engine materials. This type of excessive contamination, due to mechanical failure, can be prevented by the NTF system. Ours is the only system that can absorb coolant and water molecules without the use of electrical heating elements.

What about acid build-up within the engine?

Corrosive acid is formed primarily from sulfur blow-by in the combustion process. When sulphur particles combine with moisture in the crankcase, acid is formed, which in turn reduces the TBN or the amount of alkaline base material in the oil. If one of the two products needed to form this acid (sulphur particles and moisture) is removed from the oil, excessive acid formation cannot take place. The NTF bypass filter maintains a high and acceptable TBN level by removing the moisture in the lube oil. To combat the non-sulphuric acids that may form in minute quantities (due to atmospheric oxidation), any small amounts of alkaline base reserve that are used is replenished with the addition of make-up oil at the time of servicing the NTF bypass oil filter.

Why have the major engine manufacturers not installed the NTF filter system as the engine is manufactured?

There are two basic reasons: First, adding aftermarket products as factory equipment drives up the price of the products. Secondly, the manufacturers have planned obsolescence built into the engines to enable them to keep selling replacement parts and engines to you, the consumer.

I’ve heard that oil “breaks down” during service and must be replaced at regular intervals to protect engines and hydraulic systems from damage.

Most experts agree that the basic properties of oil do not change during service. Oil can, however, become contaminated by particles and moisture to the point that it cannot protect the lubricating system from wear and corrosion. Contamination can be reduced and maintained at low levels with the use of ultra-fine filtration. NTF ultra-fine filtration can extend the useful life of oil 80-90% in engine crankcase lubrication systems.

I have full flow filters on all my equipment. Aren’t full flow filters adequate for keeping oil clean?

Full flow filters do what they are designed to do, which is to remove solids in the 15-25 micron range. They are not designed to remove particles in the so-called wear range (the .5-15 micron clearances found in bearings, pumps and valves), nor do they remove moisture or varnish compounds which form in oil. Over the life of the equipment (even well maintained equipment) varnishes and sludge can form on parts and clog valves, seals, pumps and fluid passages.

How does NTF maintain oil at levels of cleanliness which are superior to new oil?

New oil frequently contains particles in the wear range which exceed the maximum contamination levels specified by the equipment manufacturer! By removing particles in the wear range, as well as the moisture and varnishes which form in oil during service, NTF actually maintains oil at cleanliness levels which exceed the new oil and equipment manufacturers' specifications.

If I install an NTF filter on my operating engine, won’t it starve my engine of lubricating oil?

No! The principal behind our 20-year success is that the system is hooked into the oil circuit “IN BYPASS.” Even if you would create a complete blockage on both the inlet and outlet lines of the NTF unit the full flow system would still be doing its job. In reality conventional oil filters can never filter effectively. They are placed in main stream of the oil circuit and need to be relatively coarse to guarantee a sufficient flow rate. The best possible retention values of these full flow filters in use today are approximately 15 micron. You must add oil to the engine to equal the volume contained in the filtration canister and connecting line. But the flow rate through the NTF element is small compared to the oil flow to the engine. No changes in oil pressure or volume will be detectable. We strongly recommend that part of the savings from using NTF be spent on quarterly oil analysis (or analysis at the usual oil change intervals). This will provide better information on engine conditions than oil changes alone, and provide assurance that the additive package and particle count in the oil makes it suitable for continued use.

Does reclaiming oil with the use of ultra-fine filtration restore the original color of the oil?

Sometimes yes and sometimes no. Some industrial lubricating fluids will show dramatic recovery of their original color, possibly to the point at which it cannot be distinguished from new fluid. Nearly every fluid will show some visible improvement in cleanliness with the removal of moisture and particles in the “wear range” (.5-15 micron) for engines and hydraulic/lubricating systems. The dark color that will remain is the dyeing effect the carbon ash has on the oil molecules. We rely on laboratory analysis to tell us how clean the oil is and that the oil is suitable for continued service.

PRESENTATIONS & ARTICLES

Here is a small portion of our Case Studies, Articles, White Papers, Presentations and more. Are you curious about how things work? If so, then Click to View More!

-

Lube Tech Presentation

Marine/Shipping Applications -

ME - july/aug 2010

Emerging Problem of lubricant Varnish -

Baldor Motor Maintenance

MSSM0274AR/9731AV - Maintenance Manual -

Reprint: Global Cement Mag. oct 2007

Motor Bearings - ABB Switzerland -

TLT: Best Practices jan. 2010

Managing Lubricant Degradation -

UpTime: june/july 11

Automatic Lubrication Systems - Don't Work!?!