- Home

- Lubrication

Systems - Lubricants

& Fluids - Lubrication

Equipment - Contamination

Control - Condition

Monitoring - Services &

Training

![]()

Lubrication Technologies

Your Professional Lubrication Management Team.

Lubrication Technologies, Inc.

120 BOSWORTH ST.

WEST SPRINGFIELD • MA 01089

August 25, 2016

YAMADA ELECTRIC GREASE PUMPS

Lubrication Technologies, Inc., of West Springfield Massachusetts, is the Sole Stocking U.S. Distributor for the YAMADA grease lubricators; a highly versatile grease pump and grease gun that can be used as a Stand-Alone Pump, with semi-automatic configurations when combined with a grease feeder distributor, lubrication lines and fittings, to create a semi-automatic system. It also has fully automatic configurations functioning as the driving pump behind a fully automatic system when combined with an electric monitor, grease feeder distributor, lubrication lines and fittings.

With over 28 years of proven field service and having sold over 100,000 units, the Yamada lubrication system is an electrically powered grease lubricator specifically designed for use on heavy construction machinery.

HEAVY EQUIPMENT ELECTRIC GREASE PACKAGE

Sets up easily and fits directly onto a 5-gallon grease pail (a 16-gallon version is also available). It works with a hose reel and hand grease gun, and can be used stand-alone or with a centralized lubrication system.

The unit’s metal follower plate features Buna N wiping seals rather than being a solid piece of Buna N fastened to a coupling. The follower plate works in straight or tapered pails, and ensures the complete removal of grease from a container.

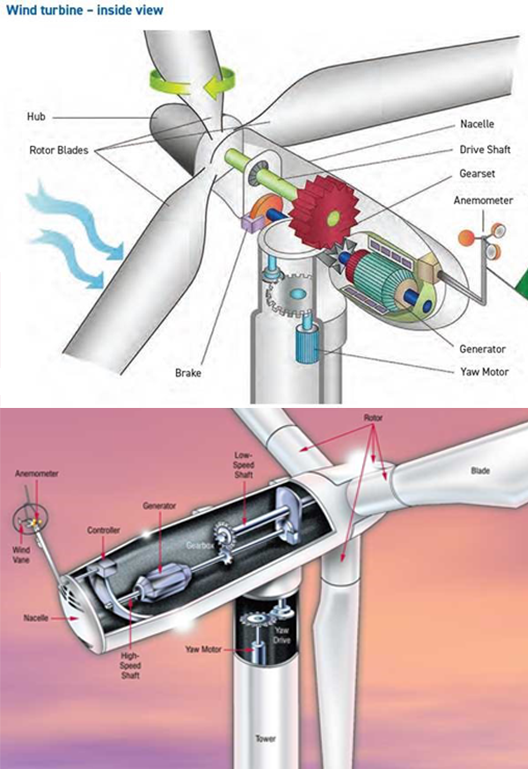

The pump can refill automated lubrication systems inside wind turbines or act as the driving pump behind the system. Its maximum discharge pressure of 4,061 psi is one of the industry’s highest. Discharge volume is 80 to 120 grams/min in continuous operation and 70 to 80 grams/min in 30-minute periods. The unit has a vibration resistance of 4G. Operating temperatures range from 14 to 104°F.

View Heavy Equipment Electric Pump Package Product Info (PDF)

Hold Down Mount

We have custom-made a laser cut, powder coated steel, Yamada Pump hold down mount that are typically used on excavators for a 5 gallon (35lb) pail of grease.

YAMADA KPL-24 Electric Lubricator

- 24 Volt DC electric connection (no tapping hydraulic or pneumatic lines) for easy installation.

- 35% lighter (26lbs) than competitor models with tip-resistent design.

- Metal follower plate construction and Buna N wiping seals for long-term operation.

- 4000 psi max discharge pressure.

Semi-Automatic Configurations - can be combined with a grease feeder distributor, lubrication lines and fittings to create a semi-automatic system.

Fully Automatic Configurations - can be the driving pump behind a fully automatic system when combined with an electric monitor, grease feeder distributor, lubrication lines and fittings.

Full Monitoring Automatic Configurations - can also be combined with low level grease sensors, blockage indicators, fault warning, intelligent electronic monitor, grease feeder distributors, lubrication lines and fittings to create a fully automated and self-monitoring system.

Quick Setup Instructions

- Rock the inductor plate on top of the grease - until it almost oozes out of the sides and center hole. This will remove any trapped air.

- Stick the pump (suction tube) through the hole in the inductor plate.

- Open Needle Valve and turn on the pump. When a steady stream (unbroken) of grease comes out of the hole in the needle valve, shut off the pump. This will remove any remaining air.

- Close needle valve

- Open gun (trigger) and turn on pump.

- When a steady stream comes out, the pump is primed and ready to go.

WIND TURBINE ELECTRIC GREASE PUMP PACKAGE

Lubrication plays a crucial role in the overall maintenance of a wind turbine system. A premature failure of a bearing or gear can cost around $100,000, and that's not including downtime. Precision lubrication of critical bearings in the powertrain demands measured volumes of lubricant which many OEM's call out.

Lubrication plays a crucial role in the overall maintenance of a wind turbine system. A premature failure of a bearing or gear can cost around $100,000, and that's not including downtime. Precision lubrication of critical bearings in the powertrain demands measured volumes of lubricant which many OEM's call out. Using our Wind Turbine Electric Grease Pump Package allows technicians to grease bearings with a 110VAC high pressure (4kpsi) pump and record the precise amount of lubricant in grams that are delivered to each bearing.

COMPONENTS INCLUDED

- 110 Volt AC High Pressure Grease Pump

- Digital Read-Out Grease Meter

- Triple-swiveling joing, rigid end + 4 jaws coupling

- Control Valve

- 34' of high pressure hose supplied

View YAMADA Wind Turbine Grease Package Product Info (PDF)

TRAIN SWITCH GREASE PACKAGE

One of the most important functions for which lubrication of railway tracks is important is the minimization of friction between the wheel flange and rail interface.

One of the most important functions for which lubrication of railway tracks is important is the minimization of friction between the wheel flange and rail interface.Lubrication is extremely important in the curves in the railway tracks, where side cutting of rails often occurs. If the rail tracks are unlubricated, the longevity of the rails will suffer, and they will need to be replaced frequently. Regular rail lubrication increases the longevity of these rails.

The KPL-24 High Pressure Electric Grease Pump has the ability to operate on just about any kind of mobile or stationary mining or construction equipment as it has a vibration resistance of 4G for all ground equipment.

Features

- High discharge pressure - 4000 psi max

- The KPL-24 is powered by 24-volt DC operation.

- Includes 50 foot 3/8" heavy duty hose reel with control valve.

- Custom made heavy-duty hold down.

- Pumps may be used in conjunction with a divider valve and a timer for automatic lubrication.

Please call to order (413) 788-5823