- Home

- Lubrication

Systems - Lubricants

& Fluids - Lubrication

Equipment- GREASE PUMPS-Electric (Yamada)

- GREASE PUMPS-Air More--->

- GREASE GUNS More--->

- Quick Release Grease Coupler (Meclube)

- OIL PUMPSMore--->

- HOSE AND REELS More--->

- LUBRICATION CARTS

- Engine Crankcase DRAINS

- USED OIL DRAINS (Samson)

- XPEL OIL CONTAINERS

- BULK STORAGE SYSTEMS More--->

- Lube System Filling Options

- Showcase

- Contamination

Control - Condition

Monitoring - Services &

Training

![]()

Lubrication Technologies

Your Professional Lubrication Management Team.

Lubrication Technologies, Inc.

120 BOSWORTH ST.

WEST SPRINGFIELD • MA 01089

August 25, 2016

OPEN GEAR LUBRICATION SYSTEMS

Lubrication Technologies, Inc. is a Distributor of Open Gear Lubrication Systems and Components

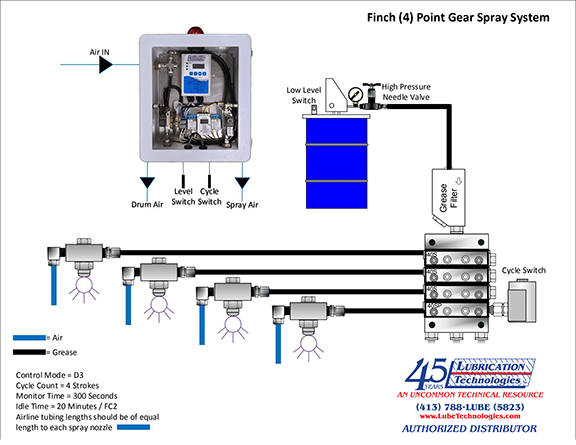

Open Gear Spray System

Open Gear Spray Systems incorporate proven intermittent spray technology to reduce lubricant consumption while ensuring open gears are properly lubricated. These systems monitor both the lubricant and airflow to the nozzle tip, ensuring the right amount of lubricant is delivered at the right time. Using one of these systems to lubricate your open gears will create more operational uptime and reduce operating costs while extending gear and pinion life.

Open Gear Spray Systems incorporate proven intermittent spray technology to reduce lubricant consumption while ensuring open gears are properly lubricated. These systems monitor both the lubricant and airflow to the nozzle tip, ensuring the right amount of lubricant is delivered at the right time. Using one of these systems to lubricate your open gears will create more operational uptime and reduce operating costs while extending gear and pinion life.

Single Line Automatic Spray System

The spray systems are used to lubricate large gear and pinion sets such as ball mills, rod mills, kilns, etc. They are widely applied in power generation, mine, cement, forging and paper equipment. These lubrication systems can increase gears working life, reduce maintenance time and costs.

Gear face widths of 50mm to 1.06m can be lubricated with nozzle. The gear spray systems operate intermittently, they can be thought of as film maintaining devices. The electrical controls provide broad cycling flexibility as well as fault monitoring and afterblow to purge the nozzles.

Twin Pump

Designed to Work All Day Every Day in Hazardous and Harsh Environments

Dualine lubricating systems are found in virtually every industry in which continuous duty operation is required. From steel production to pulp and paper, from mining equipment to machine tools, automatic application of the lubricant provides significant benefits to the equipment user. There are several components that are used in designing a Dualine system:

- Valves

- Reversing Valves

- Central Stations

- Controllers

Dualine Systems are economical for a system with more than 20 bearing points and lubrication points can be added easily without redesigning the total system. A blockage between feed line and bearing will not shut the system down, ensuring that the remaining bearings will continue to be lubricated. There are positive lubrication indicators for each bearing point enabling easy monitoring for any blocked points. Dualine systems have the ability to positively displace a broad range of lubricants from light oil to grade 2 grease. Lubrication discharge volumes at each lubrication point are fully adjustable in the field, even after start-up.

View Dualine Electric Pump-TWIN Engine PDF

Beneficial Qualities

- Compatible with high viscosity synthetic open gear lubricants

- Controlled intermittent lubricant spray with unmatched pattern accuracy

- Programmable controller for simple adjustability

- After-blow to purge nozzles of grease

- Reduced vibration and noise

- Standalone design can be retrofitted with ease

- Proper lubrication combined with the correct LE open gear lubricant will help reduce gear temperatures during operation and reduce wear rates of pinion and bull gears.

Lubrication Technologies also carries a wide selection of automotive and open gear lubricants, as well as greases for industries where large open gears are in service, including: coal-fired power generation, mining (iron, copper and other minerals), cement.