- Home

- Lubrication

Systems - Lubricants

& Fluids - Lubrication

Equipment- GREASE PUMPS-Electric (Yamada)

- GREASE PUMPS-Air More--->

- GREASE GUNS More--->

- Quick Release Grease Coupler (Meclube)

- OIL PUMPSMore--->

- HOSE AND REELS More--->

- LUBRICATION CARTS

- Engine Crankcase DRAINS

- USED OIL DRAINS (Samson)

- XPEL OIL CONTAINERS

- BULK STORAGE SYSTEMS More--->

- Lube System Filling Options

- Showcase

- Contamination

Control - Condition

Monitoring - Services &

Training

![]()

Lubrication Technologies

Your Professional Lubrication Management Team.

Lubrication Technologies, Inc.

120 BOSWORTH ST.

WEST SPRINGFIELD • MA 01089

August 25, 2016

Our Work

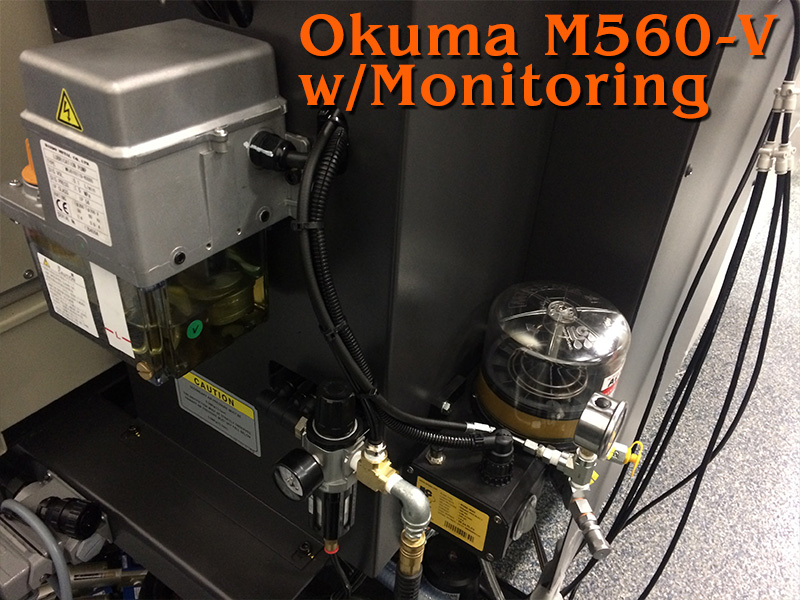

OKUMA M560-V w/Monitoring

The Okuma Genos M560-V has a flexible, operator-friendly design with the table moving on the Y axis for easy loading and unloading of parts, room on the table for adding a 4th axis, and a 32-tool front-access tool changer that is separate from the machining area for access even while the machine is still cutting. Every day, companies with machinery and equipment incur the high and hidden costs associated with the outdated method of manual lubrication. Manual lubrication requires that every system be stopped and shut-down for grease lubrication.

In addition, operators and maintenance personnel must climb on, in, and around the systems to perform the regular task of manual lubrication. The high costs of machinery downtime, the ineffective method of manual lubrication, and the risk of a recordable accident, requires today’s companies to review and implement newer and alternative methods and technologies.

Over 50% of All Bearing Failures are Lubrication Related.

Lubrication Technologies offers automatic lubrication systems that provide the following benefits for today’s modern machinery and equipment:- Increased production up-time

- Increased machinery reliability

- Extended machinery service intervals

- Elimination of machinery downtime due to manual lubrication

- Increased operator and mechanic safety

- Reduced unplanned downtime

- Increase in machinery residual value

Eliminate Manual, point-by-point lubrication on machinery and equipment of all types:

- Pumps

- Molding Machines

- Turbines

- Packaging Machines

- Aerospace

- Gun Manufacturing

- Paper Machines

- Power Plants

- Etc...

PRESENTATIONS & ARTICLES

Here is a small portion of our Case Studies, Articles, White Papers, Presentations and more. Are you curious about how things work? If so, then Click to View More!

-

Lube Tech Presentation

Marine/Shipping Applications -

ME - july/aug 2010

Emerging Problem of lubricant Varnish -

Baldor Motor Maintenance

MSSM0274AR/9731AV - Maintenance Manual -

Reprint: Global Cement Mag. oct 2007

Motor Bearings - ABB Switzerland -

TLT: Best Practices jan. 2010

Managing Lubricant Degradation -

UpTime: june/july 11

Automatic Lubrication Systems - Don't Work!?!

Pittsfield Fire Department, Pittsfield, MA

Saving $9,000 per year in component replacement!

“We used to purchase the cheapest lubricants we found, now with 3750 my front end parts and king pins last longer, the life of the spring hangers has been extended, and the old grease still looks red!” Read more

Saving $9,000 per year in component replacement!

“We used to purchase the cheapest lubricants we found, now with 3750 my front end parts and king pins last longer, the life of the spring hangers has been extended, and the old grease still looks red!” Read more

Tom Scherben

Pittsfield Fire Department

Master Mechanic

Master Mechanic

Quinn Brothers Inc., Essex, MA

Saved $92,400 over a five year period since converting to LE lubrication program!

“We cannot say enough about the service Dave Piangerelli supplies, as well as the products, top notch in our book! The installation of the lubrication system is the single, most cost-effective option on a truck.” Read more

Saved $92,400 over a five year period since converting to LE lubrication program!

“We cannot say enough about the service Dave Piangerelli supplies, as well as the products, top notch in our book! The installation of the lubrication system is the single, most cost-effective option on a truck.” Read more

Jay & Joe Coughlin

Quinn Brothers Inc.