- Home

- Lubrication

Systems - Lubricants

& Fluids - Lubrication

Equipment- GREASE PUMPS-Electric (Yamada)

- GREASE PUMPS-Air More--->

- GREASE GUNS More--->

- Quick Release Grease Coupler (Meclube)

- OIL PUMPSMore--->

- HOSE AND REELS More--->

- LUBRICATION CARTS

- Engine Crankcase DRAINS

- USED OIL DRAINS (Samson)

- XPEL OIL CONTAINERS

- BULK STORAGE SYSTEMS More--->

- Lube System Filling Options

- Showcase

- Contamination

Control - Condition

Monitoring - Services &

Training

![]()

Lubrication Technologies

Your Professional Lubrication Management Team.

Lubrication Technologies, Inc.

120 BOSWORTH ST.

WEST SPRINGFIELD • MA 01089

August 25, 2016

Lubrication Management - It's What We Do!

This is what we provide, a comprehensive approach to machine maintenance.

1-3% of a Maintenance Budget

1-3% of a Maintenance Budget

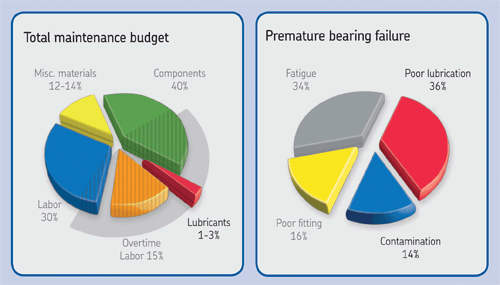

As noted in the pie chart, the cost of lubricants typically represents 1-3% of a maintenance budget. Contrast that fact to the impact of improper or insufficient lubrication:

The cost of failed components and overtime due to machine downtime can total as much as 40% of maintenance dollars spent. This fact highlights the importance of a well-functioning, proactive lubrication management program.

The most frequent causes are related to lubrication: As the second pie chart notes, approximately 50% of premature bearing failures are due to issues such as too much or too little lubricant; lubricant contamination or cross-contamination with incompatible lubricants; lubricant-chemical degradation; and use of the wrong type or grade of lubricant.

Precision Lubrication Management Approach

Typical lubricant vendors or jobbers offer a number of different lubricant lines, many of which compete with each other. We represent one lubricant manufacturer and have for over 45 years: Lubrication Engineers Lubricants.But, it’s not about the lubricant, it’s about your assets. Your assets produce the revenue that supports your company. CEO’s, plant managers and those involved in the management of assets are concerned with productivity, profitability and sustainability.

And those goals are aligned with ours as we offer an effective precision lubrication management approach that relies on Reliability-Centered Maintenance or RCM, a process to ensure that critical assets function at peak performance regardless of the harsh environmental conditions in which they run as well as Best Practices.

We are NOT a typical lubricant vendor!

Our holistic perspective to the management of your lubricants which are as much an asset as your wheel loader, injection molding machine or paper machine is in fact our hallmark for we look at your assets and the funds that are allocated to support them as if they were ours. At the end of the day, what matters is the profit you make with the assets you have and we are here to support that.

Saving time, resources and money while increasing the reliability of your equipment is at the core of our mission. At Lubrication Technologies, Inc, we understand the science behind reliability-centered maintenance and the critical role that a Precision Lubrication Management Program will play in achieving higher levels of equipment reliability, enhance personnel safety, superior machine performance and of course profitability. That's why we offer 360° solutions to help you identify and prevent equipment failure and maximize machine life.

Our extensive field experience and willingness to help our clients REDUCE their lubricant consumption makes us the preferred partner to work with when it comes to achieving the lowest lifecycle cost of owning and maintaining revenue producing machines.

PRESENTATIONS & ARTICLES

Here is a small portion of our Case Studies, Articles, White Papers, Presentations and more. Are you curious about how things work? If so, then Click to View More!

-

Lube Tech Presentation

Marine/Shipping Applications -

ME - july/aug 2010

Emerging Problem of lubricant Varnish -

Baldor Motor Maintenance

MSSM0274AR/9731AV - Maintenance Manual -

Reprint: Global Cement Mag. oct 2007

Motor Bearings - ABB Switzerland -

TLT: Best Practices jan. 2010

Managing Lubricant Degradation -

UpTime: june/july 11

Automatic Lubrication Systems - Don't Work!?!